Posted to News on 21st May 2009, 11:17

Belt-driven linear positioner achieves higher performance

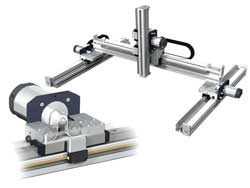

Mclennan Servo Supplies is launching a new and innovative long-travel belt-drive system that is claimed to offer higher dynamic performance, increased accuracy and improved repeatability compared with conventional belt-driven linear positioners. The ServoBelt from USA-based servo-mechanics company Bell-Everman uses a patent-pending design based on two steel-reinforced polyurethane timing belts that are meshed and guided through a servo-driven toothed roller and idler system held within a carriage supported on linear motion guide bearings and Bosch 45 series T-slot extruded profile.

As the active belting under tension is effectively restricted to less than 75mm, regardless of the travel range, a much increased and uniform stiffness is possible when compared to conventional belt-driven systems. This means that servo tuning can have much higher gain factors and superior settling times, allowing significant dynamic performance improvements throughout the travel range or the ability to use less powerful motors to achieve the same results. The design also considerably improves both positional accuracy and repeatability specifications for belt-driven systems, particularly for applications with longer travels.

Standard ServoBelt units cover travel ranges from 340-6040mm in 60mm increments and has an out-of-the-box bidirectional accuracy to +/-60um, unidirectional repeatability of +/-10um, acceleration to 4 'g' and speeds to 5m/s. In short, the units cost a similar amount to conventional belt-driven positioners but with a dynamic response normally associated with screw-driven units and a performance close to that available from linear motors.

Multi-axis capability

The adaptable ServoBelt may be configured as a single-axis unit or for multi-axis Cartesian robot systems, complete with energy chain cable management if required. The carriage has NEMA 23 and 34 frame sized servo motor mountings with a choice of five motor power ratings available with 16,000 and 20,000-line rotary encoders.

A wide range of standard and wrap-around rail options is available with single or dual linear motion guide bearings. ServoBelt technical data, available from Mclennan, includes motor sizing for peak axial thrust up to 889N and load ratings for pitch, yaw, roll and shear type offset loads, and for normal loads with a moving mass of up to 5.35kg.

The design can also accommodate multiple moving carriages on the same axis for increased versatility, or multiple motors can be installed on the same carriage for increased thrust. Carriages can move or be held fixed with the rail being moved - allowing a host of design possibilities for large-format handling and assembly systems in packaging, processing and manufacturing equipment.

Requiring minimal maintenance, the ServoBelt system is lubricated for life with stainless steel hardware for maximum durability. Options include infinitely adjustable limit sensors and performance enhancement can yield an axial repeatability of just 2um with a 1um linear encoder option; higher speeds are available on request.

Mclennan can assist with design and commissioning for complete systems and can supply ancillary equipment to complement the installation of the ServoBelt system.