Posted to News on 18th Sep 2012, 14:39

Compact universal pneumatic valve terminal saves time and cost

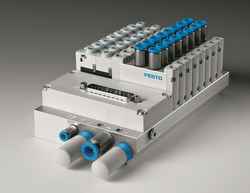

Festo is launching the VTUG pneumatic valve terminal that delivers high performance in a compact and robust unit. The cost-effective VTUG multipin terminal is a simple-to-apply universal valve that has many electrical connection options, giving machine builders and end users versatility for ease of control and installation.

VTUG valve terminals give excellent performance with a high flow rate and high pressure for their compact size, and are suitable for use in food, beverage, packaging, electronics, semiconductor and light assembly industries where assured performance is essential. The VTUG valve terminal is connected and controlled via D sub or ribbon cable connectors for easy connection and simple system integration. This multipin connector can be easily swapped for an iport connector for connection to the industry-standard IO-Link network as well as to many fieldbus and industrial Ethernet protocols.

There are various pneumatic port connection options available with the valve terminal, including semi-inline, sub-base and a sub-base option with working ports underneath, making it well suited for control cabinet installation, as the manifold itself forms part of the cabinet. This enables the fast build of cabinets and saves on the cost of separate gland plates for tubing.

The VTUG is described as a robust and reliable terminal, and is available with up to 24 valve positions on a single valve terminal, and with two 3/2 valves in one position up to 48 functions can be achieved on one manifold. According to Festo, alternative products do not have as many valves on one manifold and, as a result, the VTUG saves cost and space as well as making machines easier to build.

These valves are suitable for low- and high-pressure operation, from -0.9 to 10bar, and can support positive pressure and vacuum on one manifold thanks to being able to create multiple pressure zones on one terminal. This means that machine builders do not need two separate manifolds, which saves cost and space. Users can easily switch between external and internal pilot air without having to specify this prior to building, so the terminal is suitable for use with vacuum or low-pressure applications. This versatility means OEMs can change the valve terminal configuration during the build without having to order additional parts.

One product for many applications

VTUG is robust and tough, with an IP40 or IP67 rating, providing reliable operation in a wide range of environments and in ambient temperatures of up to 60degC.

Festo's VTUG pneumatic valve terminals operate with air filtered to 40 microns, so only one air filter is required in the air preparation system. With some alternative products, air needs to be filtered three times, to five microns in particulate size. However, each time air is filtered, energy is lost, so using the VTUG can improve energy efficiency.

VTUG is said to be exceptionally easy to order using Festo's online configurator. Users simply enter their specifications and the configurator produces one part number and a 2D or 3D CAD drawing. The terminal is then delivered, fully assembled, in just one week.

Jacqui Hanbury, the product manager at Festo, says: "The VTUG is one of the most economic, reliable and simplest to use universal valve terminals with a long service life. It is pre-built and tested before being delivered, so it arrives ready to plug in, which means it is exceptionally easy to install, therefore saving time and reducing errors and risk of air leakage associated with having to build a terminal from separate parts."

For more information on the VTUG multipin pneumatic valve terminal go to www.festo.co.uk/vtug. For information on Festo's full range of pneumatic valves and the online configurator visit www.festo.com/gb or telephone +44 (0)800 626 422.