Posted to News on 7th Nov 2006, 22:38

ELAU and PWR co-operate on robotic packaging machinery

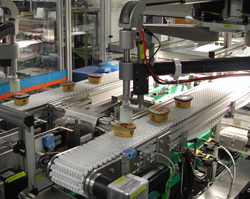

In the past, robots were only used in the packaging process for end-of-line applications such as palletising. In the meantime, however, a whole new trend has arisen: the integration of robotics in primary and secondary packaging processes to achieve increased flexibility.

Robots are becoming capable of handling the same jobs as conventional machines and material handling systems - and in a fraction of the space. The choice of kinematics depends on criteria such as whether two- or three-dimensional movements are required, and which loads are to be positioned within which cycles.

ELAU is working together with PWR to create complete systems for the integration of robotics for packaging machine manufacturers. As a specialist in robot-supported packaging systems, PWR has all the products required for integrating robotics modules, including diverse robot mechanics and deliveries as well as gripper and vision systems. Customised robot kinematics can be integrated as modules that are tightly synchronised with the rest of the packaging machine using the PacDrive robotics functionality available from ELAU.

PWR's Unigrabber 2 Toploader is excellent for loading cartons. It is fast, light, low-maintenance and guarantees a high degree of flexibility where products and packaging are concerned. The Unigrabber 2 is equipped for medium-weight products being fed into a collated product flow with static product removal positions.

However, the Unigrabber 3 has been specially designed for high speeds, and the horizontal working area is very flexible - despite the small dimensions. A vision system makes the Unigrabber 3 able to grab light products of up to 0.8kg out of a chaotic product flow and to set these in the packaging. The advantages of a vision system compared with a static feed are obvious: packaging small goods such as chocolates and biscuits is much more efficient and more flexible.

Using the Pin Point vision software opens up new possibilities for differentiation in image detection and processing. The software even helps to detect different and irregularly formed cuts of meat. In this application, the co-ordinates are transmitted to the ELAU PacDrive controller in real-time to control the robots and the feed and transport conveyors.

Advantages of the complete robotised system are:

- Seamlessly co-ordinated competences

- Bundled know-how from two packaging specialists

- System responsibilities for the overall application from a single source

- A common controller for packaging machines, integrated robots and feed conveyors

- Simplified robot integration

- Time and cost savings