Posted to News on 2nd Nov 2009, 10:15

Festo launches low-cost electric actuators type ELGR

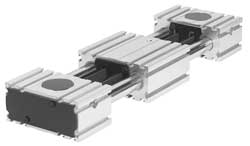

Festo is entering the low-cost electric actuator market with the launch of a toothed belt drive axis that marries cost-optimised design with precision engineering. Costing 65 per cent less than Festo's popular EGC series high-performance electromechanical axes, the new ELGR toothed belt axis is claimed to set a new price-performance standard for the motion control industry. Designed primarily for applications involving relatively short strokes and low moments on the guide, such as pick-and-place tasks and movement of small masses, the ELGR axis is also suitable for positioning, centring and pushing functions on conveyor belts, and for opening guards on processing machines.

Unlike conventional toothed belt axes that feature a full-length profile, the ELGR axis is only supported at either end and relies on the rigidity of the steel bearing guides to ensure straight-line movement of the carriage. Both the support ends and the carriage are constructed from the same extruded aluminium profile - an innovative asymmetric extrusion geometry facilitates the necessary offset - which further helps to minimise cost. Provided that system designers keep applied torsion and bending forces within prescribed limits, Festo's ELGR axes are capable of repeatable positioning accuracies of +/-0.1mm and a very high in-service life - in excess of 5000km of travel.

ELGR axes are available with a choice of 35, 45 and 55mm wide profiles, and the moving carriage can be equipped with sliding bushings or ball bearings for higher speeds and loads. Different models within the range offer stroke lengths from 50mm to 1.5m and speeds up to 3m/s. The largest model can generate a feed force of up to 350N and accommodate payloads as high as 30kg.

Component compatibility

All ELGR axes are compatible with Festo's latest-generation SIES-M8 inductive sensors, which provide an elegant means of handling end-position sensing. The sensors fit flush within slots in the support ends of the axis and detect the presence of a flag plate on the moving carriage. Each sensor features an LED status indicator and, since both sensor and target are external to the axis and clearly visible at all times, commissioning adjustments can be handled with ease.

The new ELGR axes are said to be particularly easy to install: a hollow drive pinion, combined with a new design of elastomer motor coupling featuring an expanding shaft, provide a simple, backlash-free connection. The motor can be mounted at either end and on either side of the axis, which means that users do not have to specify motor placement at the time of ordering but can leave this decision until installation if they so wish.

A number of configuration options further enhance the design-in flexibility of ELGR axes. They can be supplied with extra moving carriages to the left, right or either side of the standard carriage, and can also be equipped with an extra long carriage for applications that demand higher load bearing capacity. ELGR axes can also be supplied with two moving carriages that work in opposite directions, making them suitable for opening and closing biparting guards on processing machines of for large-format gripping applications. For special applications, Festo can also supply ELGR axes without the bearing guides, or with extra long strokes.

ELGR toothed belt axes are available as standalone products or as part of a complete motion control system; they are fully compatible with Festo's range of stepper and servo motors, as well as the company's modular multi-axis system. The axes can also be used with any third-party motors; Festo can provide flange designs for these motors and even manufacture them if required.

Follow the link for more information about Festo's ELGR toothed belt axes.