Posted to News on 6th May 2015, 13:12

Henkel to showcase thermal management expertise

The upcoming PCIM (Power Conversion Intelligent Motion) event in Nuremberg, Germany is where Henkel will highlight the latest addition to its portfolio, Bergquist thermal products. Acquired in late 2014, The Bergquist Company is a market leader in thermal management materials is now a core component of the Henkel portfolio for its global electronics customers. From Hall 9, Booth 520 over May 19-21, the Henkel team will showcase several of its innovative thermal products, along with the company's recently introduced solder paste and semiconductor materials.

Effectively managing the thermal load of power devices will be a central theme at this year's PCIM and Henkel's T-Clad insulated metal substrates offer a robust option. Developed by Bergquist, T-Clad substrates are suitable for higher watt-density applications where high currents are the norm. The materials' ability to minimise thermal impedance and efficiently conduct heat makes T-Clad a more effective thermal management substrate material than conventional printed circuit boards. Applications such as motor controls for battery-driven vehicles, LED lighting and power conversion all benefit from the use of T-Clad to facilitate thermal management.

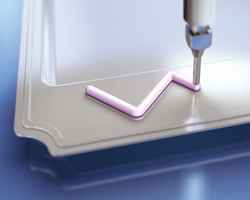

Throughout the 3 days of PCIM, the Henkel booth will host live demonstrations of Gap Filler material deposition on board dispensing partner RAMPF's DC-CNC250). Also a Bergquist innovation, Gap Filler materials are thermal interface formulations provided in a liquid medium for greater flexibility and manufacturing automation as compared with traditional film-based products. Available in a range of formulas that provide thermal conductivity levels from 1 to 4 W/m-K, Gap Filler materials provide the ability to control thickness, adapt for device topography and eliminate assembly stress for sensitive components. The use of liquid Gap Filler products also enables manufacturers to more fully automate the thermal interface application process, thereby increasing throughput and lowering overall cost.

In addition to talking to the Henkel team at the stand, show delegates who are interested in learning more about Gap Filler products should attend a technical presentation at 11:40 a.m. on May 19th. Mr Holger Schuh, Henkel Product Manager and Application Engineer, will deliver a presentation entitled "Thermally Conductive, Cure-in-Place Gap Filler as an Optimal Solution for High Efficient Cooling" at the Exhibitor Forum 7-260.

Loctite phase change heat transfer pastes

Along with these advanced materials, Henkel will showcase Sil-Pad, Gap-Pad Bond-Ply, Hi-Flow and Liquid-Bond thermal products throughout the PCIM event, in addition to the successful Loctite phase change heat transfer pastes Loctite TCP 4000PM and newly-introduced Loctite TCP 7800NC for higher temperature operation. Both materials are designed for stencil printing an integrated layer on power modules with the lowest thermal resistance.

Henkel will also use PCIM as an opportunity to introduce its latest solder paste development, Loctite GC 10, to the European electronics community. The first-ever temperature stable solder paste, Loctite GC 10 offers manufacturers outstanding performance and cost savings throughout the logistics and operations chains. Stable at 26.5degC for 1 year and at temperatures of up to 40degC for 1 month, Loctite GC 10 eliminates the need for cold-packed, overnight shipping and on-site refrigerated storage. On the line, the stability of the material extends print abandon times and stencil life, delivers a start-up time of zero and provides consistent print transfer efficiency. Reflow performance is also exceptional with an expanded reflow window and increased activity for better results with soak temperatures between 150degC and 200degC.

Alongside the company's next-generation solder paste, Henkel will highlight semiconductor materials specifically formulated for the needs of power devices. Loctite Ablestik ABP 8064T is a high-performance die attach paste with 20W/mK thermal conductivity. It has excellent stability at high temperatures and can be a suitable replacement for soft solders in medium power applications. Mold compounds are also an area where Henkel has a strong innovation portfolio. At PCIM, visitors are invited to learn more about Loctite Hysol MG 15F-MOD2 C high Tg (245degC) mold compound, which is compatible with emerging silicon carbide (SiC) technology and is designed for use with high-voltage and high-power device applications.

For more information about thermal management materials, visit www.henkel.com/electronics and www.bergquistcompany.com. To schedule an appointment at PCIM, send an e-mail to [email protected].