Posted to News on 13th Jun 2012, 16:00

Inline thermal imager spots defects in injection-moulded parts

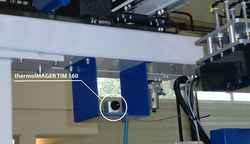

Micro-Epsilon has developed an inline, non-contact temperature measurement system for the quality control of injection moulding machines. The thermoIMAGER TIM thermal imaging camera is installed in the injection moulding machine in order to detect defective parts. The camera uses the thermal radiation from the workpiece to detect not only visual faults, but also hidden defects within the material itself.

In addition to Micro-Epsilon's operating software, SKZ also developed control software designed specifically for plastics processing, which visualises the workpiece and compares this with an infrared reference image. SKZ has integrated the thermal camera into the injection moulding machine to enable users to control and automatically remove any defective parts. The system also ensures rapid, secure machine changeovers, as any newly produced parts are evaluated immediately after changing the mould tools. This continuous quality control is particularly useful to automotive suppliers, where the value of injection-moulded parts increases by several hundred per cent as the parts are processed.

Powered and operated via a USB 2.0 interface, the thermoIMAGER TIM 160 is an inline radiometric thermal imaging camera that provides temperature images and profiles of a target area. This plug-and-play unit comes with a full software package (included in the unit price), that enables the user to configure all the parameters of the device, as well as enabling the real-time capture and storage of images or video of an event for slow-motion play back or snapshots at a later date - an important feature in many R&D and failure diagnostics work.

Micro-Epsilon's latest addition to the range is the thermoIMAGER TIM 400 and 450 inline infrared thermal imagers. These cameras capture and store thermal video and images with very high optical resolution (382 × 288 pixels) at a full frame rate of 80Hz. The cameras are equipped with new detectors, which provide excellent thermal sensitivities of 80mK and 40mK, respectively. This enables the cameras to detect even smaller changes in temperature. The TIM400 is available for less than 5000 and the TIM450 for less than 6000 - described as significant price breakthroughs for infrared video capture cameras of this resolution and performance.

Follow the link for more information about Micro-Epsilon's thermoIMAGER TIM series or email [email protected].

No. 1 Shorelines Building

Shore Road

CH41 1AU

UNITED KINGDOM

+44 (0)151 355 6070