Posted to News on 22nd Jul 2007, 18:52

Long-travel gantry positioning stages achieve high throughput

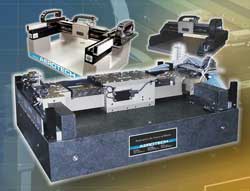

Aimed at high-throughput, automated production and test applications, Aerotech's extensive range of long-travel gantry positioning stages use brushless direct-drive linear servo motors and precision feedback systems to deliver micron to sub-micron accuracies with up to 3m/s speed and acceleration to 5g. The complete range covers five models based around linear motion guide or air bearing technologies, complete with cable management systems for maximum life and minimal maintenance. Feedback systems include non-contact linear encoders or dual-axis interferometers to suit micron- to nanometre-level resolutions. As with all Aerotech positioning systems, custom engineering is available to modify standard designs to add Z and rotary axes, parts handling adapters, special fixtures and complete machine base structures that can accommodate machine control electronics.

The low-cost, entry-level AGS1000 is available for X-Y positioning of up to 500 x 500mm with a calibrated accuracy of +/-5um per axis when used with Aerotech motion controllers. Maximum load is 15kg and repeatability is just +/-2um. The modular assembly features sealed linear motion guide bearings and e-chain cable management and is designed for use in high-speed pick-and-place, automated assembly, vision inspection, dispensing stations, and high-accuracy inspection systems. A dual linear motor arrangement on the lower X axis can include a second encoder to improve control and accuracy. The AGS1000 may be bolted directly to the customer's machine base or supplied on a sturdy aluminium base plate.

For longer travel ranges, heavier payload, improved accuracy and higher speed capability, the AGS10000 and AGS20000 gantry systems use larger linear motion guide bearings systems with integral seals and cable management. Both models can provide high-throughput X-Y precision positioning for up to 1000 x 1000mm at speeds of up 3m/s and acceleration to 3g, depending upon system resolution (from 0.005-1.0um, based upon a selection of encoders and multipliers). With a single lower (X) axis linear drive motor, the AGS1000 provides a load capability to 25kg, best calibrated accuracy of +/-5um and repeatability to +/-2um. The precision-optimised AGS20000 uses a dual lower axis drive and encoders for a 30kg payload and can achieve a calibrated accuracy of +/-3um and +/-1um repeatability.

Magnetically pre-loaded air bearings

For the ultimate in long travel, ultra-precise positioning, Aerotech offer two gantry-based systems with magnetically pre-loaded air bearings to provide optimised stiffness and load distribution. Both the ABG10000 and the ABL9000 series are supplied with dual X axis linear direct drives in standard travel ranges up to 1000 x 1000 mm.

The ABG10000 uses dual-axis, non-contact linear encoder feedback to extend the performance capability of the gantry range shaving accuracy to within +/-2um and repeatability to +/-0.5um using Aerotech's HALAR calibration. Based upon a choice of 20um or 4um nominal encoders, final system resolution is between 0.005um and 1.0um. A maximum Y axis payload of up to 9kg allows adequate margin for customer fixtures or Z, theta positioners in high-speed pick-and-place, automated assembly or dispensing station applications. Speeds of up to 1m/s and accelerations to 0.5g are achievable, depending upon the required system resolution. Aerotech's magnetically preloaded air bearing design also provides excellent precision in pitch, yaw and roll, making the gantry suitable for vision inspection and micro-machining applications. The ABG10000 series may be supplied as a modular system for direct fixing to the customer's machine or with a custom-supplied granite or other type of machine base designed to accommodate the entire electronics subsystem.

At the top end of the range, the ABL9000 series air bearing gantry positioning systems can meet and exceed the exacting demands of high-throughput production and test applications in wafer, flat panel display, optical inspection and fabrication. With pitch, yaw and roll to within 2arc-sec and a maximum load of 100kg, this range is available to order with a choice of non-contact linear encoder (LN) or laser interferometer (LZR) feedback systems to provide positional accuracy below +/-1um for the 1000 x 1000 mm travel version. X-Y position resolution with multi-axis interferometer feedback is from 0.3-79nm and this system will also control Y axis yaw to less than 1arc-sec.

Micron-level incremental moves

For ultimate performance, these stages use cog-free direct-drive brushless linear servo motors driven with state-of-art linear amplifiers for micron-level incremental moves and the fine speed control necessary for velocity-critical scanning applications. Furthermore, sophisticated control-based features such as temperature compensation and orthogonality correction result in performance that is claimed to be unsurpassed for long-travel, high-throughput precision systems.

To exactly match customer's requirements, ABL9000 gantry systems are available with modified travel lengths, different cable management schemes, customised granite assemblies and specialist fixtures as fully engineered systems.