Posted to News on 31st Jan 2014, 10:33

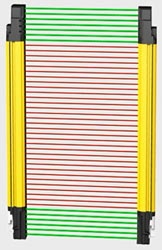

New advanced multifunction light curtains with no dead zones

Pilz is launching the PSENopt Advanced safety light curtains that are exceptionally versatile thanks to their multifunctional capability; muting or blanking and cascading are implemented within the same light beam device. Additional features include a genuine 'no dead zone' area at the top and bottom, configuration either manually or through software, and logging. The new PSENopt Advanced safety light curtains therefore offer distinct advantages over the existing basic range from Pilz.

The main feature of these light curtains is that they can be manually or software configured for standard, blanking or direct muting capability, with an extra bonus in that the devices can be cascaded.

Light curtains with no dead zones

With the top and bottom beams located at the extremes of the receiver/transmitter, there are no dead zones; these light curtains can therefore be fitted into tighter spots without extraneous housing getting in the way.

Hand protection in corners

Cascading

33 types of advanced multifunction light curtain

The new Advanced range consists of 33 types covering Type 2 hand (30mm) and Type 4 finger (14mm) and hand (30mm) resolution, at protected heights ranging from 300mm to 1800mm, with operating ranges of 0.5 to 20m. The light curtains are supplied with sliding fixing brackets, and a separate cascading bracket it also available. Reaction times are as fast as 11.9ms. The devices are TUV certified to EN 61496-1, IEC 60508 to SIL 3 and EN ISO 13849-1 to PLe.

Connections can be made at the top or bottom of these light curtains via easy-to-fix 18-pole pigtail leads, of which there is an emitter type and two receiver types, one for normal or blanking use, and one for muting which will accept two independent, hardwired muting inputs (as required in IEC/TS 62046) directly into the receiver.

Basic configuration made easy

Advanced configuration

PSENopt Configurator software can be used online or offline, and there are three levels of password protection to ensure safety configurations cannot be tampered with by, for example, maintenance engineers using the software for online diagnostics.

Coding

Pilz also offers a range of protective stands, mirrors and IP6k9k tubes. Together with Pilz PNOZ or PSS controllers, PLe and SIL 3 safety systems can be built. Pilz also offers an accredited Stop Performance Monitoring test service to assist users in determining the correct safe distance at which light curtains (and other safeguarding measures) must be placed in accordance with EN ISO 13855.

Pilz has prepared a short animation that demonstrates the functionality of these new light curtains: Light curtains PSENopt - safety with perspective.

Follow the link for more information about the PSENopt Advanced safety light curtains. Alternatively, telephone +44 (0)1536 460766 or email [email protected] to discuss particular applications.