Posted to News on 11th Apr 2017, 16:21

Piezoelectric strain sensor has fully digital charge amplifier

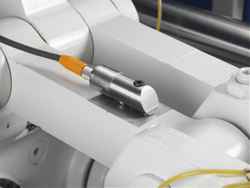

The new Type 9238B piezoelectric strain sensor from Kistler Instruments monitors the force-proportional strain on machine components and structures. The integrated charge amplifier produces an industry standard +/-10V output making the sensor simple to integrate into existing systems and measuring chains.

Typical applications include:

- Machine monitoring, such as protecting mechanical presses against overload

- Quality assurance in production runs for joining processes, such as wobble riveting, clinching and resistance spot welding

- Monitoring machine tools, such as prompt detection of tool breakage or tool collision

The 9238B is much easier to install than bonded strain gauges. Secured to a suitable clean, unpainted position on the machine frame by a single M6 screw, the sensor is especially easy to retrofit to almost all types of machine tools. The sensor measures dynamic and quasi-static strain on machinery or structural surfaces. Force can be calculated knowing the material stiffness and component geometry. Alternatively, the signal can be calibrated against an appropriate standard to provide absolute measurements in N or kN.

Kistler's new piezoelectric strain sensor has two measuring ranges that can be adjusted to a particular value or signal curve in one hundred steps using either dedicated ManuWare software or directly by the machine's own PLC. When the measuring range is adjusted, the setting is stored by the integral electronics. The range can be switched remotely, even under load conditions, enabling very low forces to be accurately measured.

Typical applications for the sensor are monitoring C-frame machine tools such as presses and automatic assembly machines, preventing overload of mechanical presses, quality control of riveting, clinching and resistance spot welding processes and detection of tool breakage or collision in a wide variety of machine tools.

The parameters of the integral charge amplifier are configured using the included ManuWare PC program. For test purposes the ManuWare software can also transmit digital measurement data (at a rate

Cable connection is by a single M12-8-pin socket, mounted either on the end or upper face of the sensor, using screened cables available with straight or right-angled connector. The excitation voltage and measuring cycle, control range switching and communications interface data are carried to the sensor via the same cable used to transmit the measurement signal. Where the integral charge amplifier is not required, the similarly specified Type 9232A may be used.

Although designed for real-world industrial applications, the new strain sensors are equally suited to research and development applications requiring ease of installation and precision combined with versatility and reliability.

More information about the Type 9238B piezoelectric strain sensor can be found at www.kistler.com.

13 Murrell Green Business Park

London Road

RG27 9GR

UNITED KINGDOM

+44 (0)1256 741550