Posted to News on 7th Jul 2008, 21:45

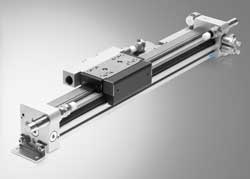

Pneumatic linear actuators have payloads of one tonne

Festo is launching two high-performance pneumatic linear actuators that extend the load-bearing capabilities of its popular DGC family. The new DGC-50 and DGC-63 actuators feature internal piston diameters of 50mm and 63mm, respectively, providing significantly higher force and payload capacities than other actuators in the same series. The top-of-the-range version of the DGC-63, for example, can accommodate payloads in excess of one tonne - approximately 50 per cent more than the previous largest model.

The DGC family of pneumatic rodless actuators now spans eight cylinder sizes, from 8mm to 63mm. Standard models within this series offer velocities up to 3m/s, forces up to 1870N and maximum 5m stroke lengths as standard. DGC actuators employ an innovative angled sealing mechanism between the carriage drive and the actuator body that ensures virtually zero air leakage and facilitates the manufacture of extra long actuators for special applications. Festo has supplied DGC actuators with stroke lengths of up to 9m to special order.

DGC series actuators are available with a choice of three types of carriage guide. The basic guide features a plain polymer bearing suitable for light loads; the medium load guide also uses plain polymer bearings running on a guide rail compactly integrated as part of the actuator extrusion, and is factory-adjusted for optimum performance; and the high-performance guide uses stainless steel caged and sealed recirculating ball bearings. The latter type can handle very smooth and high-speed movements, has zero backlash and is capable of accommodating loads that apply a high moment torque to the carriage, such as with cantilever and offset loads.

Mid-position stop and control

Further increasing the versatility of the DGC series, Festo is also introducing a wide range of additional functions that can be configured, priced, built, tested and delivered as a single assembly. These include a mid-position stop module called a DADM unit and a neat integrated displacement encoder. The DADM caters for motion sequences that require any number of intermediate positions, such as workpiece handling. It is easily mounted on the actuator and is cost-effective for dynamic applications demanding high mid-position accuracy. The DADM is suitable for both right- and left-hand approach movements, enabling the full dynamic performance capabilities of DGC series actuators to be realised.

The displacement encoder can be used for measuring or closed-loop positioning control, providing a compact positioning system as a lower cost (and lower dynamic performance) alternative to electrical servo axes.

Festo assembles DGC actuators at its central production centre, providing delivery of standard actuators within a few days, and is also able to offer customers a 24-hour emergency actuator replacement service.