The BASIS Mass Flow controller range focuses on providing accurate and fast flow control.

Full scale flow ranges 100 SCCM to 100 SLPM with a measurement and control range of 0.1% to 100% of full scale (1000:1 turndown). Nine user-selectable gases are stored internally and this allows it to be used in a variety of industries such as producing consistent batches in glass production and mixing gases in molar ratios. The fully field selectable gases included are Air, N2, O2, CH4, He, H2, Ar, CO2 and N2O.

Accuracy of the device is gas dependent on gas but is as good as either ±1.5% of the reading or from ±0.2% of full scale. Flow repeatability is also excellent at ±0.25% of reading or ±0.05% of full scale. Control response times can be as fast as 100ms. A range of flow control scripts can be programmed using the ASCII command set and dosing and batching can be achieved through an built-in totalizer.

Device accuracy is dependent on full scale and the gas being used with the device.

See the below table for better guidance:

| Fluids | Mass Flow Accuracy 1 |

| Air, N2, O2, CH4 | ± 1.5% reading or ± 0.2% full scale 2 |

| He, H2 | ± 1.8% full scale |

| Ar | ± 1.5% reading or ± 0.5% full scale 2 |

| CO2, N2O | 100 SCCM – 2 SLPM: 1.5% reading or 0.5% full scale 2 5 – 20 SLPM: 2.0% reading or 1.0% full scale 2 50 – 100 SLPM: 3.0% reading or 2.0% full scale 2 |

1: Stated accuracy is at calibration conditions, after tare, under equilibrium conditions, includes repeatability and linearity.

2: Whichever is greater.

To view the full specifications please refer to the PDF spec sheet in the 'Data sheets and manuals' section.

Devices are rated up to a maximum pressure of 12 barg, dependant on the full scale flow. Please view the technical specifications for full details. The device operates within an ambient and gas temperature range of 0 to 50°C and can handle up to 95% non-condensing humidity. It features an ingress protection rating of IP 40 and experiences a maximum pressure drop of 850 mbar for controllers.

Standard models come in full-scale flow ranges of 100, 200, and 500 SCCM, as well as 1, 2, 5, 10, 20, 50, and 100 SLPM. We also offer custom full-scale flow ranges and manifold options. Contact us today to discuss your specific flow requirements, or begin customising your product online by clicking the "Configure Now" button below.

Common process applications and industrial uses include:

The Alicat Basis 2.0 - OEM Gas Mass Flow Controller is widely used in the following industries:

Call us

01953 609930

Email us

sales@pctflow.com

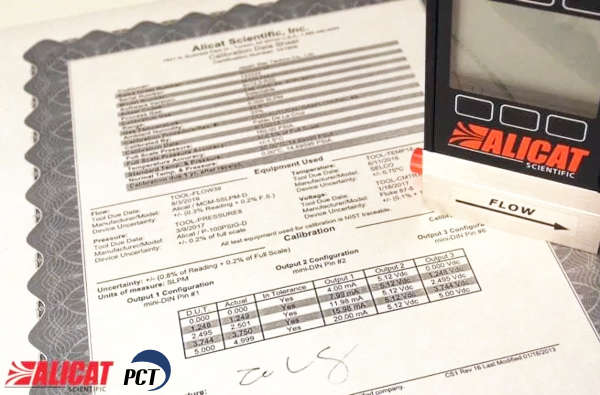

We provide a certified annual recalibration service on all Alicat mass flow meters and mass flow controllers. Further details on our recalibration service.

Please provide your contact details below.

PCT are a leading UK distributor and your enquiry will be handled with the utmost professionalism. Please provide your details below.