Posted to News on 16th Nov 2016, 16:10

Renishaw and Dassault Systèmes pool expertise for metal AM

Renishaw is collaborating with Dassault Systèmes as part of its commitment to provide and enhance software for metal additive manufacturing (AM).

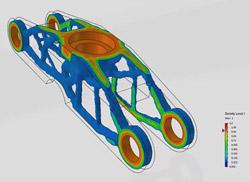

Users of Dassault Systèmes' 3DExperience platform applications can now design, optimise, simulate and set up AM builds directly for production on Renishaw's AM systems, which build 3D metal parts using laser powder bed fusion technology. Dedicated CATIA applications include a range of tools to develop and perform topological optimisation of parts. DELMIA is employed to generate the process from build setup to generation of the necessary laser paths (scan paths). Simulation of the entire AM build, including stress analysis and distortion prediction, is carried out in SIMULIA.

Both Renishaw and Dassault Systemes have software that is accessible to authorised third parties and this played a key role in the collaboration. It ensures the scan paths generated by DELMIA are optimised for Renishaw metal AM systems and produce quality builds. This open ecosystem ethos enables collaboration with other experts working towards the common goal of creating a streamlined AM software experience.

Time and cost savings

Stephen Anderson, Renishaw's Director of Group Software, explains: "The 3DExperience platform coupled with QuantAM enables parts to be produced accurately from the outset, which is of tangible time and cost benefit to users. It marks the beginning of many enhancements we have in the pipeline to improve the AM user experience and streamline the front-end of the manufacturing process."

This process control software is part of Renishaw's wider mission to provide end-to-end systems for innovative manufacturing and support the managed integration of AM (sometimes referred to as 3D printing) into the production workspace.

Renishaw has a heritage of developing software programs for its metrology and healthcare products, where accurate measurement of complex parts and verification against CAD models are critical. By collaborating with Dassault Systèmes and other experts in their fields, Renishaw seeks to foster an environment where the best software tools can be advanced for AM users.

Follow the links for more information about Renishaw's additive manufacturing products and Dassault Systemes.