Posted to News on 7th Oct 2007, 11:25

Ultra-lightweight slides offer extreme performance

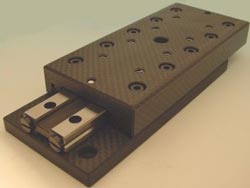

Micromech is introducing new slides from PM Bearings that are made from composite materials that consist of a matrix weave and a reinforcing weave of a specially developed carbon-fibre polymer. The bearings can therefore achieve the stiffness and strength of steel bearings but with a lower weight than aluminium versions. Micromech is the exclusive UK agent for these slides that deliver extremely high performance.

The engineers at PM wanted to develop slides that were ultra-lightweight, ready-to-install and could match the specifications of aluminium crossed-roller slides while meeting the demands for higher dynamics. Such requirements are necessary for high-speed component placement applications where mass and rigidity are important issues. The use of carbon-fibre composites was the answer to achieve ultra-smooth motion and ultra-light linear slideways. Tables are pre-lubricated with oil and this gives a maximum of 30,000km travel under normal operating conditions in which the load ratio C/P is 10 and the velocity is 1m/s.

Furthermore, the rolling resistance of the slides is exceptionally low because of the significant reduction in moving mass and the precision finishing of the reference surfaces.

Carbon-fibre composite slides offer a substantial advantage, as, compared with aluminium slides, the mass is around 55 per cent lower. In addition, there is a dramatic saving in energy consumption, hence downsized motors and drives can be used. Another benefit is that, due to their strength combined with a reduced body size, the slides fit in a much smaller envelope, which contributes to further overall savings is space, weight and cost.

Cage options

The slides are available with two types of cages, depending on the mounting orientation. For horizontal installations the slides are supplied with a cost-effective lightweight steel cage type AA. Vertical models are supplied with brass cage type DD to take up the higher loads due to gravity.

To prevent cage creep in extreme or dynamic applications, the slides can be delivered with an Anti-Cage Creep (ACC) feature that does not affect the rolling resistance or accuracy, but increases the operational life to its limits. The PM Bearings ACC feature is claimed to be the best anti-cage creep design available on the market. The all-metal design provides dependable service in the most demanding of applications where other designs containing plastic components may fail.

The carbon-composite slides offer many advantages: first, since all mounting surfaces and fitting edges are finished by precision grinding, the accuracy is equal to that of aluminium linear slides, so achieving ultra-smooth motion. They are also highly suitable for ultra-high dynamic applications, as the exceptionally low moving mass, in combination with first-class crossed-roller ways, offers excellent performance at higher accelerations up to 25 'g'. Their high stiffness characteristic results in excellent rigidity in all directions.

Standard ultra-light slides are a drop-in replacement for other industry-standard slides, yet they can also be manufactured to customer specifications, thereby offering maximum flexibility for specially designed applications.