Posted to News on 24th Sep 2014, 13:54

WaveHandling modular conveyor and sorter for delicate objects

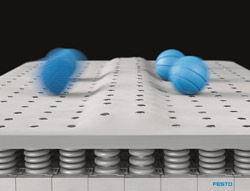

Festo has developed the WaveHandling pneumatic conveyor system for transporting and simultaneously sorting delicate objects. Steve Sands, the Product Manager at Festo, says: "Delicate FMCG products, like fruit and vegetables, require particular care in their handling and transportation if they are to make a timely arrival to market with minimum damage losses. Their limited shelf-life means that time is of the essence. In such cases, it is believed that industry can learn a lot from natural principles, and wave technology is one such principle. The new WaveHandler pneumatic conveyor concept could help the food and packaging industry make huge cost savings."

The conveyor consists of numerous bellows modules that deform the surface, creating a wave motion that transports the objects in a targeted manner. Inspiration for this principle was provided by monitoring natural waves. The movement of wind over the smooth surface of the water produces small ripples, which grow as the wind pushes against them. However, it is energy being moved by the waves, not water. The water molecules within a wave move up and down in a circular motion, but remain in roughly the same place. Yet the energy produced causes the wave to roll over the surface of the sea. The WaveHandling system behaves in a similar way: while each individual bellow advances and retracts in the same spot, a wave moves over the surface of the conveyor.

Festo's WaveHandling system utilises forward-thinking technologies based around Web4.0 concepts. Autonomous actuators, comprising 216 connected pneumatic bellows modules, are attached underneath the covering that forms the surface of the conveyor. Each module consists of bellows on top, an integrated standard Festo MHA1 valve and the appropriate electronics for actuating the valve. The bellows structure is pneumatically driven and can expand and contract by around 1-2cm. The conveyor is supplied with power and control commands, via a CAN bus, by a compressed air channel and an electrical cable running through all the modules. Each identical module recognises its position in the network and is programmed to understand its role.

Targeted movement

Being modular in design, the WaveHandling system could be positioned in the centre of a conveying unit to distribute the goods to downstream conveyors on either side. The time and effort needed for installing the conveyor is reduced since an additional handling unit is no longer required for the sorting process. Individual modules can be connected as required and are self-configuring, which opens up new opportunities in applications where subsystems need to be quickly and flexibly integrated into production sequence.

Sands concludes: "Whether it is decentralised intelligence, high transformability or plug-and-produce, the principles of the factory of tomorrow are already playing an important role in today's products."

Follow the link for more information about the WaveHandling pneumatic conveyor system, watch a video and download a brochure.