Posted to News on 11th Feb 2021, 09:35

5 questions to ask when selecting a compression latch

Compression latches and other touch point solutions are often overlooked by end consumers, but these products play a vital role in the overall appeal of the application as a whole. Compression latches have the power to make a significant impact on the performance, ergonomics and security of an industrial product or application. With a wide variety of compression latching solutions available, how does a machine builder know if they are choosing the best product to fulfil the needs? Southco provides this white paper to help guide machine builders

Here are five questions to ask when choosing the appropriate compression latch for an equipment application:

What are the specific application requirements?

Compression latches provide a robust solution to hold doors and panels shut while at the same time eliminating noise, panel movement or rattling caused by vibration. They can also compress a gasket to provide sealing against environmental elements such as water, dust and electromagnetic interference.

In order to choose the proper latch for the application, it is important to understand how much compression is needed. Different applications may require different amounts of compression, depending on the vibrational forces present and the size of the gasket to be compressed. Heavier duty applications may require latches with a lever in order to provide increased mechanical advantage to provide higher latching forces, while at the same maintaining a lower operating effort for the user.

For a precise fit and quick installation, a compression latch with a fixed grip is an ideal option. A fixed grip does not require adjustment during installation, and typically provides minimal intrusion into the space being sealed. These are best suited to applications that do not need to compensate for gasket set, have tight manufacturing tolerances, or do not need field adjustment due to system wear. In comparison, an adjustable grip can provide a range of grip dimensions that compensate for system tolerances, can be set specifically based on application variances, and allow one latch to be used in multiple applications thereby reducing both long-term maintenance and management costs.

In what environment will the compression latch be used?

This question is important when considering the choice of material, and the general strength and construction of the latch. First, it is important to understand how the latch will be used. For example, a latch may need to be opened and closed several times a day for many years, which requires a supplier to validate that the latch can accomplish its intended function over a very long lifecycle. In addition, the amount of force that the latch must withstand during normal operation or unexpected events may dictate that the latch be made out of a stronger material such as zinc or stainless steel.

The physical environment may also present additional challenges for a latch. Exterior applications may require the ability to withstand sun and wind exposure, or chemical exposure due to weather or cleaning solvents. These factors can help determine the appropriate material choice to withstand the elements and continue to provide the expected function over time. External factors can also include sealing against moisture, rain or water spray, which can lead to different latch sealing choices to protect the enclosure interior. Many customers require compliance to industry-specific standards, such as fire, vibration and sealing (such as the IP65 rating for dust and water resistance or the NEMA 4 rating for ingress of water), which require latch suppliers to perform testing to validate that their latches will perform consistently in harsh environments.

How will the latch be installed?

Installation requirements are an important aspect in the search for the ideal compression latch because in many cases, it must fit a limited design footprint. For applications with limited mounting space, a smaller compression latch that only requires a single mounting hole may be chosen. In addition, the thickness of the panel to which the latch will be mounted is an important factor that will help direct the selection of the appropriate compression latch.

Another key consideration in selecting a compression latch is the internal space inside the application for latch placement. If internal space is at a premium, a latch selection can be made that mounts on the outside of the application and provides minimal intrusion into the space. On the other hand, in order to reduce the potential risk for clothing or unwanted articles accidentally catching on the latch, a flush mounted or recessed latch can be selected.

What are the ergonomic and security requirements?

How will the panel that the latch is attached to be opened and closed? How will the latch be operated? Is there a separate handle to aid in opening the enclosure to which it is attached? These are important questions to consider when choosing the appropriate compression latch. Depending on end user preference, compression latches can be opened by pushing a button, lifting and turning a handle, turning a knob or rotating a tool. For latches that are accessed by hand with some frequency, a latch that provides an ergonomic solution such as a T-handle or knob may be desired. These are also beneficial if the user needs to access the application while wearing gloves.

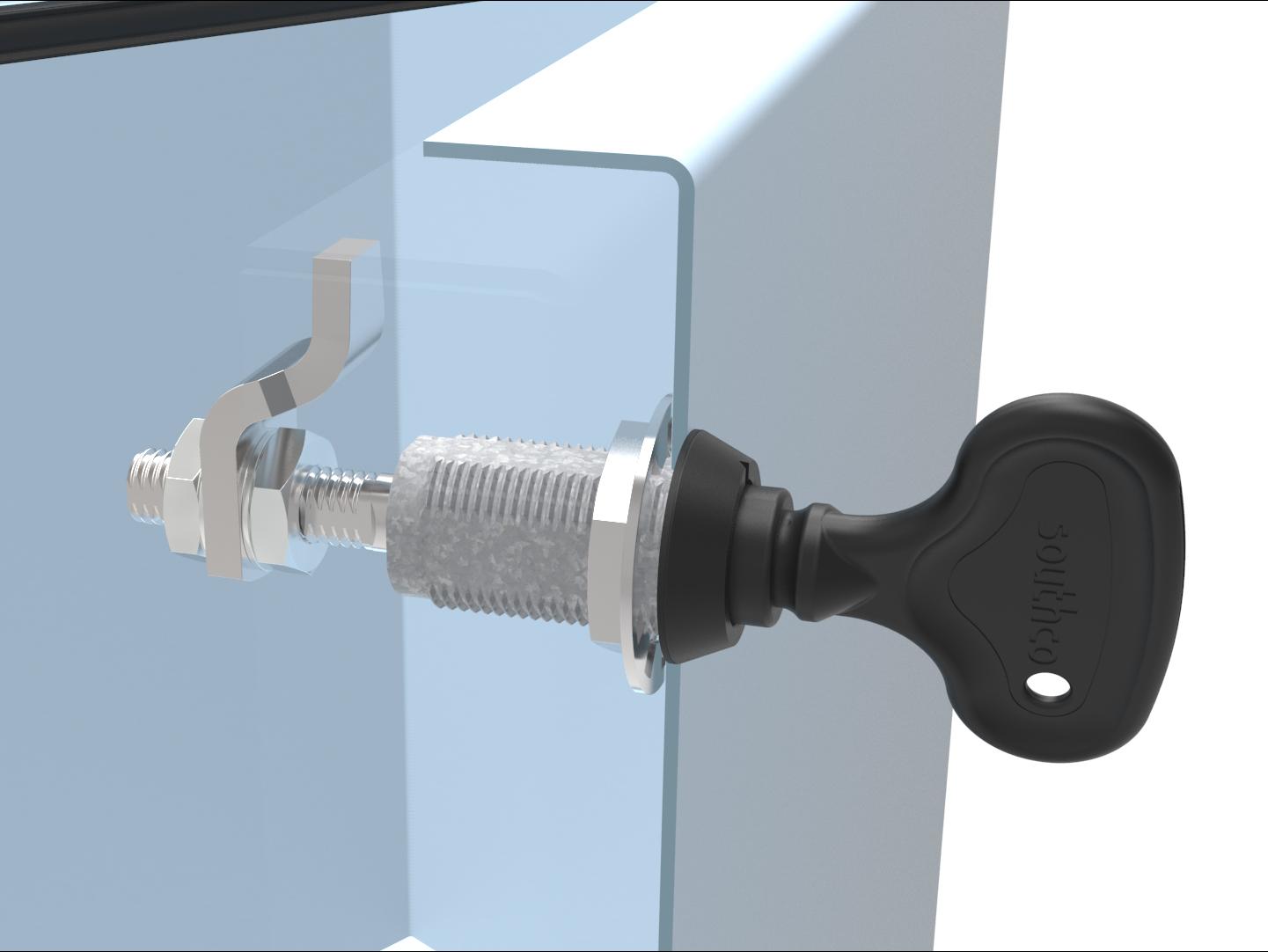

In secure environments, it may desirable to limit access to authorized personnel only. A simple compression latch may meet basic requirements for security, but there are other options to provide advanced security. For example, latches that require specific tools may limit the ability to open the latch. For applications that protect controlled environments, such as storage lockers that house pharmaceuticals, various key locking options are available to further limit the access to those individuals who have the correct key, thereby limiting the risk of theft or vandalism.

Latches can also incorporate features to alert the user of previous access (such as visual indication that the compartment has previously been opened), or provide a key retention feature to make sure that the latch is fully engaged before the key can be removed from the lock, increasing confidence that the latch has not been left open. In applications where it is important to verify that many latches are properly closed from a distance, a latch with a visual indication feature may be desirable.

What other factors are important to compression latch selection?

While environmental requirements and security needs are typically some of the most important factors in selecting a compression latch solution, other factors such as the application’s aesthetic needs may also be important.

As consumer preference increasingly considers aesthetic as a major buying benchmark, it is important to consider how the end product will look. Is the latch visible to the end customer? If so, are there high aesthetic standards for this product? Answers to these questions can help clarify the choice of material and finish of the compression latch, with options ranging from polished to chrome-plated. For instance, in the Marine industry flush-mounted and chrome plated compression latches complement the design aesthetic with a clean, shiny and protrusion-free appearance while at the same time offering durable, lift-and-turn operation. For Off-Highway industry applications, such as excavators or backhoes, latches that use a common tool for actuation and are painted black may fit better with the more industrial exterior design aesthetic, and be better suited for a construction environment.

Why choosing a reliable supplier is important

When selecting a compression latch, it is important to ensure it is coming from an established and respected supplier that has the capability to work directly with an OEM’s engineers to help identify the specific needs of their application. Since these products are extremely specific and often require customization, it is crucial for the supplier to collaborate effectively to maximise the application’s efficiency, yet minimize its liabilities.

A good supplier will not just meet industry standards for safety and reliability, but will strive to exceed them. The longer the supplier has been involved in the production of compression latches, the more likely they are to understand the unique application requirements and be able to provide the best products and customer service. Engineers should seek a supplier that can deliver the product’s promised function and durability, while also providing customer service that exceeds expectations.

Learn more about Southco's range of Compression Latches by clicking here.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>