FUJI TEKKO unifies motion, I/O and information communication using CC-Link IE TSN

Winding is a key process in a range of industries from food and beverage, agriculture and electrical engineering to automotive manufacturing, construction and consumer goods. It enables the production of products as diverse as the safety film in your car windscreen and the battery in your mobile phone. The continual development of this mission critical process has been the guiding principle of Japan's FUJI TEKKO since its foundation in 1954, explains John Browett, general manager of the CC-Link Partner Association Europe.

11th June 2025

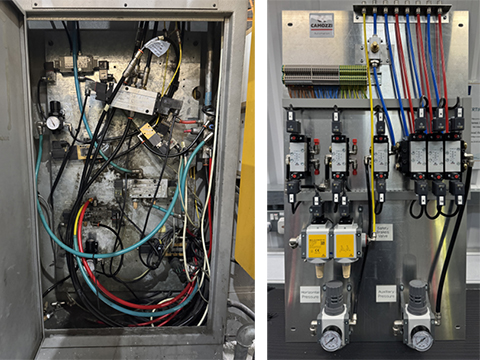

Camozzi Automation delivers plug-and-play pneumatic upgrade for leading kitchen manufacturer

When a leading kitchen manufacturer was struggling with a series of outdated pneumatic backplates which control their production lines of kitchen cupboard assemblies, it turned to Camozzi Automation.

10th June 2025

IMI boosts uptime and efficiency at Chinese plant with 3D printed valve trim

In an APAC first, eleven 3D printed valve trims, complete with ABJ soft seat, engineered by IMI have boosted uptime and efficiency at a Chinese power plant at substantially lower cost than a full valve replacement.

10th June 2025

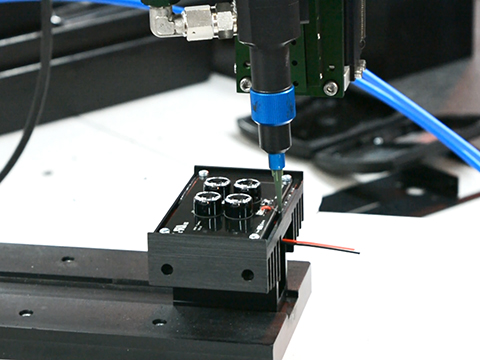

Automated dispensing helps security manufacturer increase throughput and quality

When intruder detection product manufacturer GJD was looking to automate a manual silicone application process, it turned to Intertronics.

9th June 2025

Efficient design of conveyor systems for food packaging

In the food, beverage and packaging industries, space for conveyor systems is limited. A Swedish machine manufacturer uses the advantages of drive technology from NORD DRIVESYSTEMS to realise a compact design with reduced drive variants for chain conveyors.

2nd June 2025

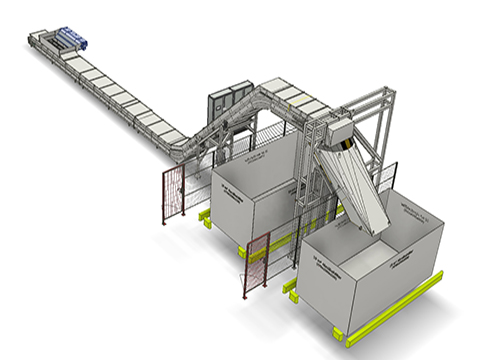

KABELSCHLEPP automates waste materials management at AGCO Fendt

Maximum productivity requires not only precision manufacturing processes, but also smooth disposal of the generated waste materials. This is exactly where the new, fully automated waste disposal solution from KABELSCHLEPP Hunsborn comes in, which has just been successfully commissioned at the factory of agricultural machinery manufacturer AGCO Fendt in Asbach-Baumenheim, Germany.

20th May 2025

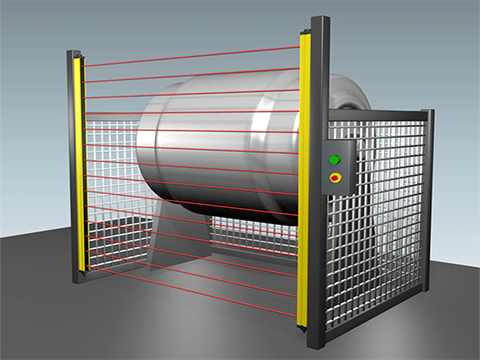

Safety curtains to protect operators from caustic wash tank

When an automotive Tier 1 producer of metal assemblies needed a reliable and robust machine safety guard to protect operators from possible injury while the degreasing is in progress, it turned to Contrinex.

15th May 2025

MiniTec hits the sweet spot with golf ball sorting

MiniTec UK is best known for its aluminium profile systems used in everything from desks and assembly benches to conveyor systems. But every so often, a project comes along that lets the company showcase just how versatile its modular system really is - and this golf ball sorting machine was exactly that.

13th May 2025

Improving quality while maximising productivity in gas sensor manufacture

When gas sensor manufacturer DD-Scientific wanted to automate the mixing, metering and dispensing of epoxy within its sensor production process, it turned to Intertronics.

2nd May 2025

Enhanced access management from Pilz ensures Safety and Security

Against the background of advancing digitisation in mechanical engineering, access management is also being put to the test: in close cooperation with the machine tool manufacturer Starrag, Pilz has developed the classic operating mode selection system into a holistic entry and access permission management system for Safety and Security tasks.

1st May 2025