Posted to News on 26th May 2021, 08:58

95% of manufacturers in survey turning to composable ERP

Manufacturers are embracing this Enterprise Resource Planning strategy on a global scale

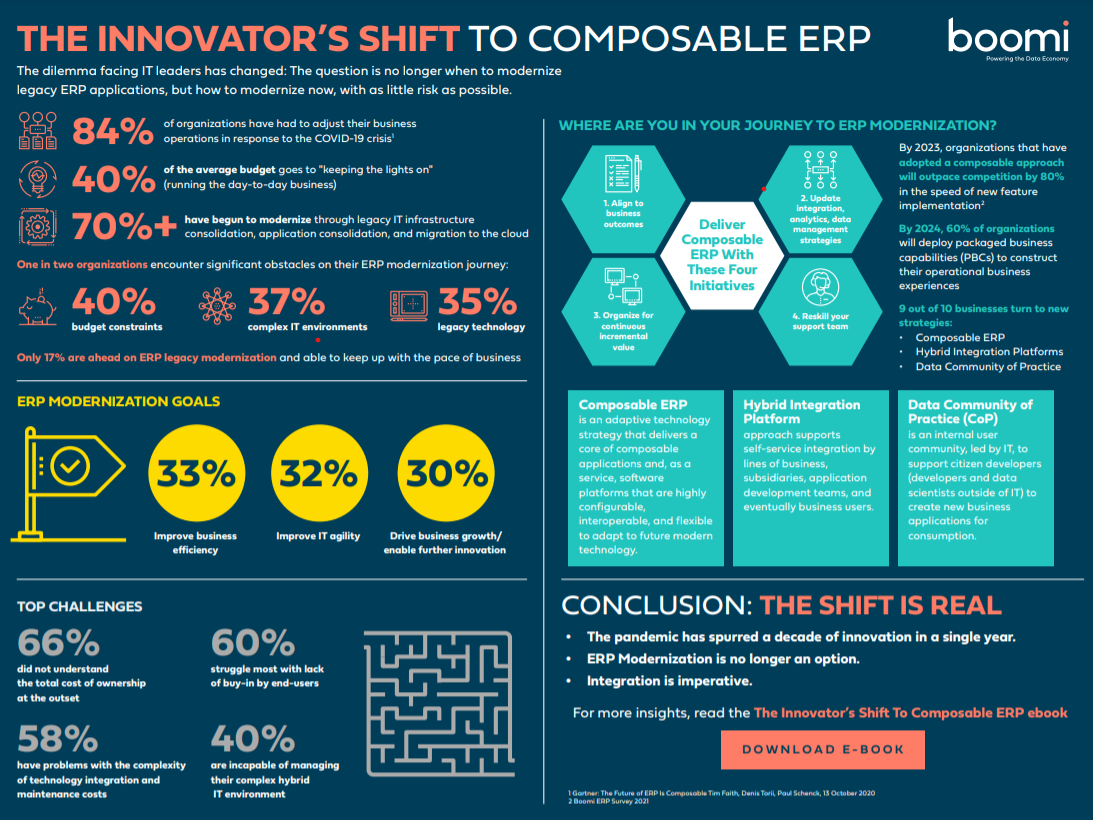

The massive take-up by manufacturers of Composable ERP - as revealed in a recent survey (a remarkable 95%) – is aimed at overcoming the limitations of legacy applications and modernise their businesses to gain a competitive market advantage. The research was carried out by Boomi, a leading provider of cloud-based integration platform as a service (iPaaS).

The independent global survey of 1,675 CTOs and enterprise architects, says Boomi, shows “manufacturers are keenly aware that their legacy ERP systems, the backbone of every organisation, are struggling to keep pace with business today. This explains the trend toward Composable ERP strategies, which give companies a flexible platform to bridge the gap between legacy and modern applications.”

Composable ERP

Composable ERP is an adaptive technology strategy that enables the foundational, administrative and operational digital capabilities an enterprise needs to keep up with the pace of business change. "These platforms deliver a core of composable applications and, as a service, software platforms that are highly configurable, interoperable and flexible to adapt to future technology," says Boomi.

Boomi’s research suggests manufacturers see the vast potential of Composable ERP, but are struggling to implement an integration strategy. In the survey, 51% of respondents said providing the best user experience possible was the motivation behind adopting integration technology.

Yet 47% indicated their current integration solutions struggle to meet their challenges. 42% say there is a high cost to maintaining these solutions, with 38% finding that they can’t cope with their complex hybrid technology environment.

Other key survey findings include:

- 97% say they are adopting a Hybrid Integration Platform (HIP) strategy to gain the flexibility to integrate applications and data wherever needed

- Benefits of modernisation by moving their ERP suites to the cloud are improving business efficiency (33%), increasing IT agility (32%) and driving business growth (30%).

- Organisations are now committed to migrating ERP suites to the cloud, while 58% predict that their ERP system will no longer be fully on-premises by 2022

- Some obstacles hindering modernisation are budget constraints (38%), complex hybrid IT environments (37%) and process roadblocks related to legacy technology (35%).

Suite 118, 80 Churchill Square

Kings Hill

ME19 4YU

UNITED KINGDOM

00 44 (0) 1732 926117