Posted to News on 14th Mar 2023, 14:06

A guide to monitor mounting arms

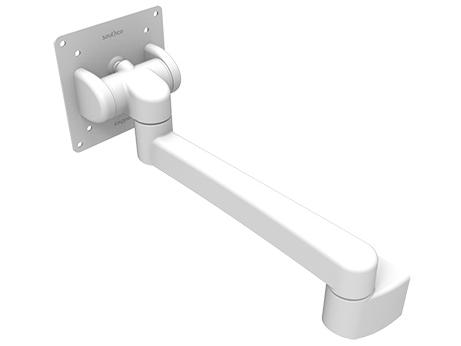

Stewart Beck, global product manager at Southco, looks how monitor mount arms work and the key design considerations when choosing one.

Monitors and touchscreens are used in a wide array of equipment applications to view and share information with operators, including self-service kiosks, surgical equipment and transportation operating systems. In response, monitor mounting arms have become a standard design requirement for applications that require frequent positioning and operation of monitors.

Engineers are now tasked with developing comprehensive monitor mount arm solutions that fit into end user applications, while considering comfort and ease of use.

Designing a monitor mounting arm from scratch however, would equal significant investment time for most engineers. Typically, most engineers source this equipment from a manufacturer who specialises in creating reliable monitor mounts. There are countless monitor mount arm designs and iterations, which can make analysing and deciding which mount to use an overwhelming task.

What is a monitor mount arm?

A monitor mount arm is a device that attaches a monitor or screen to any surface. Monitors come in all shapes and sizes to accommodate the unique needs of any given application. A monitor mounting arm should be able to successfully carry the weight and size of the screen that is attached to. Engineers also need to account for various movements that some end applications require, and how that will affect the functionality of the chosen monitor mount arm.

A screen or monitor may need to be adjusted based on end user height, preference, application use, screen glare and other factors. Ensuring that the operator can easily and safely move a monitor is a more difficult task than some would think. The final monitor mount arm design can vary greatly depending on how it will be used by the person operating it.

Monitors can be easily adjusted to individual user preferences when the appropriate monitor mounting arm is incorporated into the overall equipment design. Monitor mount arms function by controlling the torque at each rotating joint, whether the monitor is tilting, swivelling or needs to be extended from a wall or pole. This enables the user to adjust the monitor to their desired position, while avoiding unnecessary movement. Constant torque is typically used in the design of most advanced and user-friendly monitor mount arms.

Common types of monitor mount arms

There are two main types of monitor mounting arms. The first type utilises clamps at the joints in the monitor mount arms that enable the end user to adjust the monitor. The clamps are typically adjusted by the user to lessen the amount of resistance in the joint, which allows the monitor to move. The clamp can then be tightened to prevent any unwanted movement.

The second type utilises friction-controlled joints utilising torque to facilitate movements. Users typically do not have to make any adjustments to the resistance of the joint in order to move the monitor around. Monitors can be moved more easily with this type of monitor mount as compared to a mount that utilises clamps.

These two types of mounted arms can incorporate different movement options depending on their design:

- Lateral movement: One or more mounting arms can enable the monitor to move side-to-side. Some monitor mounts allow horizontal movement of a few inches, while others can move several feet.

- Height movement: A monitor mounting arm can enable vertical movement of the monitor, while fighting the forces of gravity. For example, a medical professional can easily adjust the height of the screen to show an x-ray to their patient, who lying down in a chair.

Additionally, monitor mount arms can be attached to a variety of surfaces:

- Horizontal flat surface: Computer monitors are often attached to a desk, which allows the user to easily move the monitor around.

- Vertical flat surface: Television monitors are typically mounted to a wall, which can be tilted or extended from the mount for easy viewing.

- Pole mounted: Engineers may need to utilise a mounted arm that can be attached to a rounded pole in various applications.

- Rail mounted to a piece of equipment: Engineers may need to attach a monitor to a certain piece of equipment with specific size and weight requirements.

The combination of these movement types and surface creates a variety of potential monitor mount arm designs. Engineers can pick and choose which monitor mounting arm suits the size and weight of the monitor, the desired range of motion and the surface type.

Do monitor arms work with any monitor?

The end use application will dictate most of the design considerations when choosing the right monitor mount. There are a number of factors in the end application that will help determine which monitor mount arms will work best for a certain application.

The weight and size of the monitor is one of the primary considerations an engineer should incorporate into the design. This can help engineers eliminate potential options from the beginning. Vibration is another force that needs to be considered. Applications where high vibrations are present, such as industrial machinery or vehicles in motion can cause monitor mount arms to loosen or drift, which can have serious implications. Larger monitors could cause injury to an end user if the mounting arm fails during operation.

The expected use of the monitor also should be taken into account. A heavy use monitor mounting arm is defined as a monitor that is adjusted two to three times a day. In the medical and industrial settings, the monitor mount arm needs to be able to handle those adjustment forces frequently throughout its lifespan. A monitor that will be infrequently adjusted requires a less complex mounting system.

VESA mounting standard

Engineers also may be worried about whether their monitor will work with their desired monitor mounting arm. Thankfully, one organisation has helped pave the way for engineers in this design aspect.

In order to create more universal monitor mount arm standards, the Video Electronics Standards Association developed a comprehensive set of standards to help ensure that monitor mounts will work with most monitors. VESA defines the distance between mounting holes and the number of mounting holes in both monitors and monitor mount arms. Using a VESA monitor mount arm can help simplify the design process, as there will be one less design aspect to take into account.

There are some applications that require a unique monitor mount arm configuration in order to meet end-user requirements. Engineers working on this type of project may run into some roadblocks when incorporating a monitor and monitor mount arms. Military projects may require customized monitor mount arms for their unique applications. Monitor mount arm manufacturers can work with engineers in order to custom fabricate a specific design that is outside the typical VESA standards.

Mounting a monitor to an arm

Another important aspect that an engineer should consider is how the end user will install the monitor mount arm to ensure proper function. Most monitor mounting arms can attach to a variety of surfaces. There may be some surfaces that are more difficult to properly secure to.

An engineer should make the installation process as seamless as possible for the end user. If a monitor mount requires two or three people for installation, an engineer may want to reconsider incorporating that mount into their final design. There are monitor mount arms that can be installed by a single user.

Engineers also need to ensure that the mounting surface can handle the loads that will be transferred from the mounting arm safely. The forces that are created at the point where the mount is attached to the surface are higher than some engineers might anticipate. The length of the mounting arm and the mass of the screen can create a force that tears that monitor right off of the surface. Engineers will need to account for and provide the proper fixtures and support.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>