Posted to News on 17th Feb 2022, 08:57

A platform for more insight

Opening up a clearer path for small- and medium-sized machine builders

Many of the very large machine manufacturers have their own platforms, have resources in software development and are making the first digital services available to their industrial customers.

But how do small or medium-sized machine builders manage this? The developers at Lenze focus precisely on this target group with their platform idea.

Timo Schuler is a software engineer and has been working for a small special machine manufacturer in the Swabian Alb for a good two years. Schuler comes from the neighbouring community, studied near Stuttgart, they know each other. He is docked with his ‘digital topics’ with the three colleagues from the company's customer service. "That's where I fit in best," laughs Schuler. But in fact his team consists only of him.

"The colleagues provide support here and there in everyday life, but actually the topics of digital business models and product development are completely up to me. The focus of our work is still on hardware." For the past six months, Schuler has been on a mission to offer his users additional digital services for ‘his’ machine. "My colleagues in customer service definitely see the opportunities, but the day-to-day business slows them down and I can't fulfil all their wishes.”

Adapt applications

From the Alb to Bremen, Germany: that's where Klaas Nebuhr from Lenze has his office, at the Hamelin automation specialist's digital site. Can he support the fulfilment of the wish? "It's great that the owner found a software engineer and hired him immediately. For a small mechanical engineering company, that's like winning the lottery," says Nebuhr happily. He is responsible for Lenze's digital business. For him, Schuler is the prime example of the challenge faced by many small and medium-sized machine builders in particular. "It's not a lack of ideas, but a lack of experts, processes and solutions that make economic sense for the OEM and are easy to adapt."

Because, in the large ecosystems and on the platforms of the automation giants, the many small and medium-sized machine builders from the Alb, but also from everywhere else in Germany or the world, would often not find themselves, says Nebuhr's team. An idea was born: "For many, the machine is at the centre of the business model, so we want to support the core business processes around the machine with digital business models and services. For this, we offer OEMs an asset 'Platform as a Service' (PaaS)."

Extensions, adaptations and integration

Another platform? "Yes, but one that is open for extensions, adaptations and integration. And, of course, GDPR-compliant," promises Nebuhr.

With his PaaS offering running on Azure, he sees himself as an enabler for SMEs. Lenze not only supplies the components, but also the security, infrastructure and initial applications, including from partner companies. These applications can be customised by the customer for his machine buyer with his own functions and designs. "Then he can pass them on to his customer ready for use and improve them together with the user in the next step."

Lenze takes the first step towards digital services with the customer. "We take him by the hand, because, thanks to our asset management, we know what could make sense for him and his customers. We sit directly in the machine with our components and know the applications very well."

OEE calculation as the first application

Nebuhr's dedication to the task is clear: "It's about the overall parquet – analogous to Formula 1. The best driver is not enough, if the car or the pit crew don't fit together. The OEE (Overall Equipment Effectiveness), for example, can also be calculated by competitors; it's about developing digital products for the small and medium-sized machine builders."

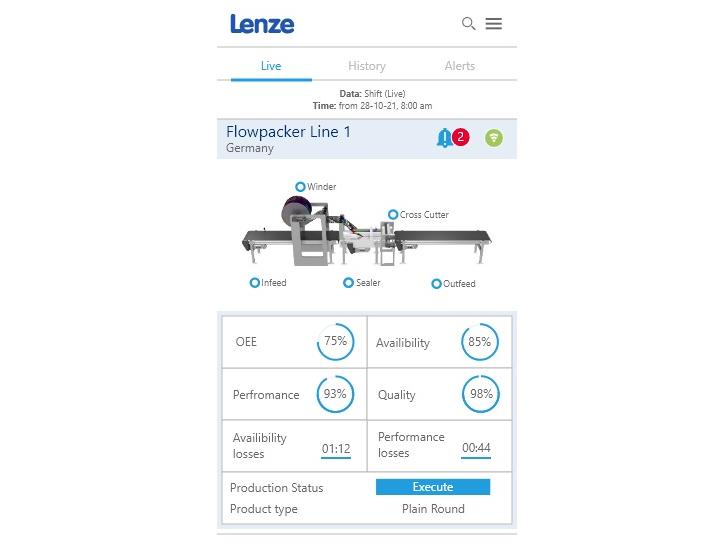

But Schuler and his colleagues are asking themselves: what might such a digital product from Lenze look like? "We are just starting with our ‘OEE & Downtime tracking’ application." Because: OEE is still the problem child in many companies. It should already be at 80 per cent. The reality is often different. There is a lack of data, but much more often a lack of transparency. This changes with OEE and downtime tracking. This provides more transparency in the production process and does so without additional hardware or sensors. The Lenze PLC calculates the OEE. "We are working on a solution that also takes other PLCs into account. The OEE solution is the first step for us and our customers."

No rocket science

The results are visualised on pre-configured dashboards. Downtime tracking is a supplement to the OEE solution. The OEE factors ‘availability’ and ‘performance’ are considered in detail, the developers say. Both machine downtimes and organisational downtimes are tracked. Organisational also includes when the machine is stopped manually or runs at reduced speed, for example.

Lenze relies on OPC UA and MQTT for communication – this ensures connectivity for future technologies. The data flow from the controller to the cloud is guaranteed and, even without a cloud connection, the live data can be sent in real time to a human machine interface for more transparency and motivation of the workforce. "Locally, we create a three-shift comparison and, in our cloud, historical data can be analysed over up to seven years," Nebuhr explains proudly.

He and his developers are certain: for the machine builder, the application is an easy way to show machine performance and availability, according to the needs of the end customers. "OEE is not rocket science, the clue lies in the provision and distribution of the application, the seamless integration into the hardware and the idea of setting up a PaaS concept, and constantly developing it further."

The end customer can increase or stabilise its production thanks to the data. OEE and downtime tracking is thus also a way to carry out production optimisations based on data.

And Schuler's role? He passes the OEE application on to his customer, so that together they can improve the machine in the future and perhaps even develop their own software modules based on it. "We don't want a Lenze lock-in," Nebuhr emphasises. Other companies are also welcome.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>