Posted to News on 31st Aug 2022, 12:23

A worked example for ROI on a dispensing robot

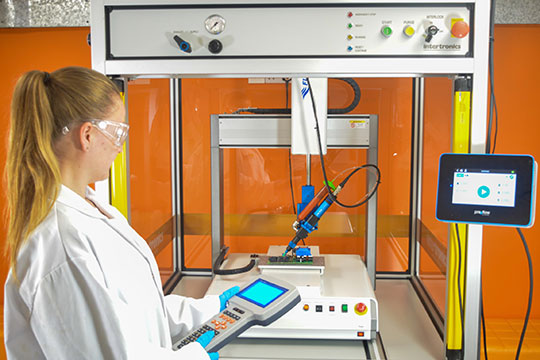

Peter Swanson, managing director of adhesives and dispensing equipment specialist Intertronics, shares a hypothetical worked example of the ROI of a dispensing robot for an electronics CEM.

The benefits of robotics are well known: improved productivity, efficiency, output, quality, and flexibility. In addition to their production benefits, they can improve health and safety and job satisfaction for employees. However, these things can be difficult to quantify against upfront costs, leaving some businesses unclear about whether their investment will deliver business value.

Here is an imagined scenario: I am the managing director of an electronics CEM. We make 1,000 potted electronics assemblies per week, regularly 200 per day. This is done manually by experienced operators. Pat is my best operator, she’s been with me the longest time.

Some weeks, about 2.5% of these are rejected after potting. Each one costs £50, so I lose £1,250 that week. The potting compound has to be mixed by hand, and dispensed into the assembly without voids or bubbles. It’s a bit of a messy and tricky job, in an area of the factory I’m not proud of.

Sometimes I have capacity problems, when the operators, especially Pat, are on holiday or sick. I worry about Pat, as she has talked to me about reducing her hours or retiring. It would be better if I could de-skill this operation to take some risk out of it.

If I invested £30,000 to £40,000 in a robot to mix the potting material and apply it automatically, we could get through all 1,000 units in half a day each week. We would still need an operator to load/unload the robot, but that could be done with someone less experienced. We think that the reject rate would go down to about 1% (and with work we could get it lower as we reduce the process variables). There would be less handling of the chemicals, improving the health and safety of my team.

Installing this automation would allow us to reallocate 4.5 days per week on labour to something more useful, saving us about £35,000 per year in labour overhead on this assembly. With the savings on rejects of about £20,000 per year, a really simple ROI sum says that we would pay off the investment in less than 12 months.

Our customer for this product has been making noises about raising the quantities from 1,000 to 10,000 per week. If that happens, we would need to hire nine more people and train them, but in this labour market, that will be really difficult. I need to keep the people I have by giving them less monotonous, more engaging work. So if we get the increased order, we would have to make the robot investment. However, I am worried that we won’t get the job unless we get our reject rate down.

One of my competitors has some of its robots pictured on its website, which makes it look really professional and up to date. Raising our image and brand would be another benefit of investing in automation, although it’s a bit more difficult to put a number on the financial value.

In conversation with our dispensing supplier, I realised that this level of automation costs much less than I thought – less than my new car. I think we can justify the cost through a fast ROI, deskilling some jobs, motivating our workforce, upping our image, and reducing risk both commercially and in production.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>