Posted to News on 3rd Oct 2022, 16:48

Achieving pneumatic cylinder longevity in harsh environments

Pneumatic cylinders are an efficient, reliable and clean solution for moving loads in a linear direction (back and forth or up and down), with good levels of force and speed. Japh Humphries, UK sales and commercial manager at Matara UK, looks at the specification considerations in harsh environment applications.

Pneumatic cylinders use compressed air as the input source to move a load. There are various pneumatic cylinder types, including single-acting, double-acting and rodless. Most contain a piston inside the cylinder, and the compressed air is pushed in at one end of the cylinder and acts upon the piston within the contained environment to translate the energy into movement, using a rod to move the external load. In the case of rodless cylinders, these are engineered to perform as a self-contained linear actuator with the piston moving within a cylinder bore, for improved flexibility.

Cylinders are often the most important component of a linear motion system. If the cylinder fails, the linear motion system is unable to function and, in most instances, the machine it is part of and even the entire production line is out of action until the cylinder can be replaced.

This downtime is undesirable in any setting, but in a harsh environment where contaminants are heavily present, standard cylinders are going to fail all the more frequently, resulting in greater downtime. Cylinders can be contaminated internally from the air supply or externally from the operating environment. In the case of the latter, seals become damaged from particles and corrosive elements in the immediate atmosphere, which are then able to enter the main workings of the cylinder, reducing the effectiveness and life of that cylinder.

Various environmental factors impact on cylinders’ longevity, but airborne particles in the form of dust and grit are the most obvious threat. If this penetrates a nose seal, it builds up and sits in seals and bearings with a similar effect to sandpaper. In a normal environment, with regular preventative maintenance, standard cylinders can cope well with basic levels of dust, but where these contaminants are prevalent, such as flour mills, mines and quarries, a more robust cylinder must be considered.

Water may not be deemed a contaminant in the usual sense, but when it comes to pneumatic cylinders it is very much a problem as where there is compressed air, there is water vapour. Furthermore, there are a number of industries, including food and pharmaceutical, where washdowns are conducted regularly and very thoroughly. In these situations, the water collects within system components where it can block the flow of air through orifices, dilute or adulterate lubricants, corrode the barrel or rod finish and, of course, freeze in cold weather.

Contamination from synthetic oils used to lubricate the air compressor can have a similar impact on cylinders to water, in that it can block orifices, as well as causing seals to swell. In harsh environments, greater quantities of lubricant are often used, which makes the contamination situation worst.

In applications where extreme heat is used, and/or where chemicals, paint or weld splatter are present, the piston rod and rod-seal are prone to damage.

Effective sealing

So, these are the problems, but what are the solutions? Let’s start with the cylinder seals, these being one of the most important means of preventing the ingress of dirt and water. Standard seals can be replaced with specialist versions to meet the needs of your specific application. Viton – a fluoropolymer elastomer and synthetic rubber compound – seals, for example, have been designed for use in some of the harshest environments, where temperature extremes and chemical interactions are common. These can readily be used in Matara’s standard rod type pneumatic cylinders and rodless pneumatic cylinders.

Moving further into the cylinder construction, with rod type pneumatic cylinders a rod seal/wiper can be incorporated to both stop contaminants from entering the inner body of the cylinder, with the wiper removing larger particulates from the rod. For added protection the rod can be fitted with a rod bellow/gaiter which keeps contaminants away from piston rods.

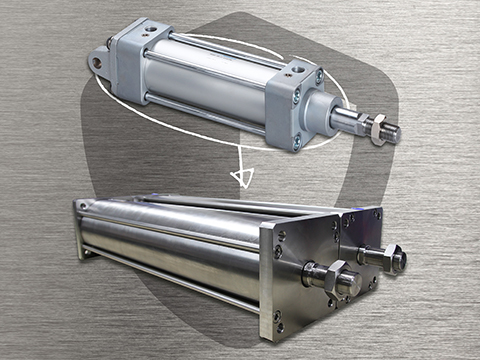

When it comes to corrosion prevention, then you may need to consider going further than just swapping out seals for more tougher versions. For corrosive environments, including those where regular washdowns are conducted, the choice of rod material may need to be reconsidered. Standard rods are mostly manufactured from chrome, but swapping to stainless-exercised steel rods and fasteners, or even a stainless-steel rod, will provide extra protection against corrosion. This will impact the cost, usually by an additional 10% of the overall cost of the cylinder. For complete corrosive protection, Matara offers a range of 100% stainless steel pneumatic cylinders.

The other option is to stick with existing materials but use specialist coatings or epoxy paints. There are a good range of options here, including Armoloy TDC coating, which Matara uses on its linear rail and ballscrews for maximum longevity in demanding applications and locations. Armoloy TDC is a hard (78Rc), thin, dense chromium coating with a micro-nodular surface texture which provides corrosion protection equal to 440 series stainless steel.

Maintenance matters

Having selected the right cylinder type for your environment, it’s important to conduct basic preventative maintenance to a regular schedule. This should include: the regular cleaning of external parts of the system so that visual inspection of seals and other parts is straightforward; inspection for wear and tear; draining of airline filters and checking that the water traps are operating as they should; lubrication of the cylinder, rod seal, piston seals and surfaces; checking for air leaks and resealing where required; and last, but not least, replacement of air filters.

Harsh environments make for difficult operating conditions, but by selecting quality pneumatic cylinders customised to your specific site, you can cost-effectively prolong the service life of a cylinder and reduce costly downtime.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 5801 Shannon Way

Shannon Place

Tewkesbury Business Park

GL20 8SL

UNITED KINGDOM

+44(0) 1684 850000