Posted to News on 18th Aug 2022, 08:53

Actuator increases accuracy and productivity of bagging machine

When end users of a precision bagging machine started using economical bags with inconsistent sizes, this impacted accuracy and productivity of the bulk bagging process.

The OEM switched to Tolomatic’s electric screw actuators as part of a new design to increase the flexibility of bag size handling. This improved repeatability and removed reliance on the machine operators, which increased end user productivity.

Whether the product ranges from fertiliser through to sugar, the filling of bags used to store and transport bulk material demands accuracy to ensure that the customer receives the agreed amount, and that the manufacturer can supply with efficiency and confidence. It’s also crucial that bags are sealed securely, and to achieve high productivity, this process has to be completed at speed, with repeatability ensured.

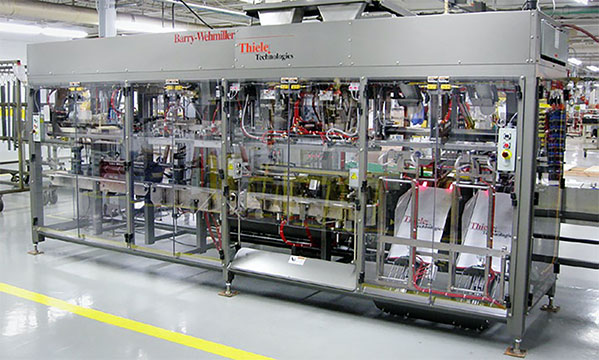

Providing bagging solutions for bulk producers in the USA, Thiele Technologies builds packaging machines that measure, fill, and seal. Despite the high repeatability of its machines, customers from the pet food market increasingly required the machines to fill inconsistently sized bags. Supplying large retail chains that were demanding more durable bags, the pet food manufacturers exchanged paper designs with woven poly types. To keep costs low for the retailers, economical bag supply was resulting in size inconsistencies, sometimes by as much as nearly 2cm, which slowed down the process, and also impacted quality of filling and sealing.

To resolve the challenge for its customers, Thiele developed a bag top reference mechanism for its machine, to compensate for the varying length bags. The new system is fully automated, removing the need for manual set up and adjustment. The result is increased repeatability and productivity of the bagging process.

The new mechanism uses four Tolomatic B3S10 rodless electric screw actuators. The actuators precisely position the incoming bags before they are inserted into the filling and sealing line. Two of the actuators adjust the vertical position of the bags, catching and lowering them to a precise reference point determined by a vision system controlled by the machine’s PLC. Meanwhile, the bags are centred in their trays by two horizontally mounted Tolomatic B3S10 actuators.

The horizontal actuators include two carriers riding on a screw, with right-hand threads on one half and left-hand threads on the other. As the screw turns, each pair of carriers moves toward each other to centre the bag in the tray. The actuators are joined by a coupler and are powered by a single servo motor, connected by a compact 180-degree Tolomatic belt drive. Once the bags are vertically aligned and centred, they are picked up by a pneumatic arm and inserted into the filling and sealing line.

Improving repeatability was a key objective. The new machine achieves a tolerance for positioning the tops of the bags of less than 1mm. Even when bag dimensions vary, this level of precision can be maintained.

The mechanism also enables the operator to change the filling and sealing specification to suit the bag size with the push of a button. Tolomatic’s programmable actuators also allow machine users to automatically adjust bag size recipes to help speed machine changeover. This removes reliance on the machine operator to ensure repeatability, and eliminates the time and wastage incurred in a manual, trial-and-error approach to sizing set-up.

Thiele also wanted to use electric, rather than pneumatic actuators, because of the speed and accuracy they provide. Tolomatic’s robust design includes a stainless steel band that seals the actuator from particulate which ultimately extends lifetime and reduces maintenance requirements for end users. The actuator manufacturer’s customisation capability, frequently applied to OEM projects, also facilitated fast, economical development. This has enabled Thiele to use multiple motor and drive configurations to provide the flexibility needed across the diverse range of their customers’ applications. This flexibility will also make it much easier to update Thiele’s bagging systems already deployed in the field.

Tolomatic is distributed in the UK by motion specialist Inmoco, whose engineers can support with engineering development, integrating with Tolomatic’s design team. Inmoco can assist UK customers with actuator specification and sizing, and thanks to Tolomatic’s ‘Your Motor Here’ design facility, OEMs can integrate their choice of servo motor with the electric actuator design.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Intelligent Motion Control (Inmoco)

4 Brunel Close

Drayton Fields

NN11 8RB

UNITED KINGDOM

+44 (0)1327 307600