Posted to News on 4th Sep 2023, 13:30

Advantages of balanced tapered section retaining rings in EV motors

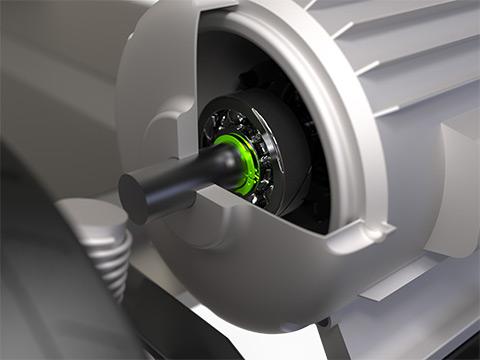

As electric vehicles (EVs) continue to gain in popularity, the demand for efficient and reliable electric motors continues to increase. Electric motor design plays a crucial role in determining the overall performance and efficiency of the vehicle. An often-overlooked component with a significant impact on performance is the retaining ring, as the experts at Rotor Clip explain.

Rotor Clip manufacturers all styles of rings. However, balanced tapered section retaining rings are a cost-effective option for high-speed applications which require a low balance/noise in the assembly. Balanced rings offer a number of advantages, including increased revolution rates, cost-effective manufacturing, fast production, simple installation and removal, and mitigated risk of fatigue in physical stop features.

Enhanced stability: Balanced tapered section retaining rings provide improved stability and security for electric vehicle motors. Their design features a taper, which allows the ring to exert consistent radial pressure on the shaft. By increasing the size of the lugs to offset the material displacement associated with the taper and rings gap, the ring weight becomes evenly balanced.

What’s innovative is the enhanced width and height of the lugs and larger MAX section, that allows for a geometry improvement at high rotational capacity. The evenly distributed pressure ensures a firm hold in the groove, minimising the risk of any axial movement or displacement. With the high-speed revolution rate commonly associated with electric motors, these rings effectively prevent the motor components from loosening or shifting during operation, reducing the chances of mechanical failure, and enhancing the overall reliability.

Reduced vibration and noise: Electric vehicle motors operate at high speeds, and any vibration or noise generated can impact vehicular performance. Balanced tapered section retaining rings help in mitigating these issues by increasing the revolution rate ranges by a minimum of 30%.

The uniform pressure they apply on the shaft helps minimise vibrations and dampen resonance within the motor assembly. Consequently, this leads to quieter motor operation and a smoother driving experience for EV owners.

Improved efficiency: Efficiency is a critical factor in electric vehicle design, as it directly affects the range and performance. Balanced tapered section retaining rings contribute to improving the efficiency of electric motors. While other ring solutions that provide a “dimple” or locking feature require striking the ring with hammers or difficult installation techniques, tapered section rings are easy to assemble.

Simple automation allows for the ring to be expanded over a mandrel for positioning in the groove. Not only does this simple process save assembly time, but it reduced the risks of damaging/striking mating assembly components. Lug holes are present for ease of removal and service.

Cost-effective solution: Balanced tapered section retaining rings offer a cost-effective solution for electric vehicle manufacturers. Their simple yet robust design allows for easy installation and maintenance, reducing assembly time and associated costs. Additionally, their high reliability and longevity minimise the need for frequent replacements, resulting in reduced downtime and lower maintenance expenses for EV owners.

Balanced tapered section retaining rings provide several advantages for electric vehicle motors. From enhanced stability and reduced vibration to improved efficiency and heat dissipation, these rings play a crucial role in ensuring the reliable performance of electric motors in EVs.

As the demand for electric vehicles continues to grow, incorporating balanced tapered section retaining rings into motor design is an intelligent choice for manufacturers aiming to deliver high-quality, efficient, and durable electric vehicles to consumers.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>