Posted to News on 22nd Oct 2014, 15:48

Airedale Springs installs 3D printer for component production

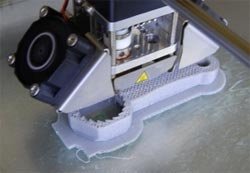

Airedale Springs is installing a 3D printer for the production of plastic components, checking gauges and spare machine parts. Fused deposition modelling falls within the general term of Additive Manufacturing, although regardless of the process it is normally referred to as 3D printing.

3D printable components are created with a computer aided design (CAD) program; the data is then converted by a special programme called a 'slicer' that converts the 3D CAD model into a series of thin layers and produces a set of instructions - known as a G-code file - that the printer will understand.

The 3D printer follows the G-code instructions to lay down successive layers of liquid plastic to build the component from a series of thin cross-sections. These layers, which correspond to the virtual cross sections from the CAD design, are automatically fused to create the final shape. The printed part is quickly cooled by two fans each side of the print head to avoid the part warping.

A thermoplastic wire held on a coil at the back of the printer in unreeled to supply material to an extrusion nozzle head that heats the material and turns the flow on and off. Servo motors move the extrusion head and adjust the flow. The head is moved in the horizontal plane and the table in a vertical direction.

The printer can print a component within a maximum size of 230x225x205mm. Two different material types can also be used, either acrylonitrile butadiene styrene (ABS) or a high-density polythene. The layer thickness of the printer is variable and can be set between 20um and 200um. The primary advantage of this printing technique is its ability to create almost any shape or geometric feature.

Airedale Springs has worked with a number of customers using their CAD drawings to print components onto which the company's wire forms fit. To date their customers have been delighted that they Airedale has been able to provide this service and provide complicated wire forms and a 'hard' model of their mating parts.

For more information on how Airedale's new 3D printing capabilities can help you, go to www.airedalesprings.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

The Spring Works, Bridgehouse Lane

Haworth

BD22 8PA

UNITED KINGDOM

+44 (0)1535 643456