Posted to News on 23rd Mar 2022, 08:55

All about the vital ‘Link’ – and the benefits it delivers

OEM Automatic offers its insights on how IO-Link simplifies communication with sensors and actuators

IO-Link, the interface for communication with sensors and actuators, is an international standard that many are embracing. OEM Automatic, which is deeply involved in the development of the automation industry, is committed to helping organisations develop and streamline their process, it states.

In this article, OEM Automatic take an in-depth look at IO-Link.

WHAT IS IO-LINK?

In short, IO-Link is an interface that simplifies communication with sensors and actuators.

WHAT MAKES IO-LINK DIFFERENT TO OTHER INTERFACES?

IO-Link is different from most similar interfaces, as it is standardised internationally, making this their most prominent feature. So, there is no need to think about whether different components from different manufacturers are compatible.

HOW IO-LINK WORKS

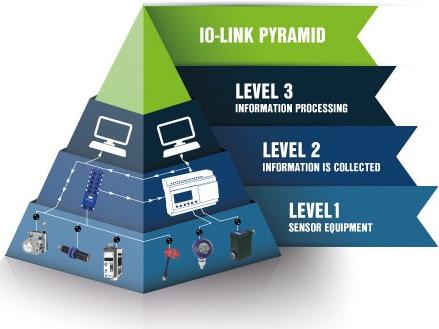

The pyramid featured here shows how different products can communicate to the same master, which passes this information on to software, which then refines the information. It is also possible to send information directly from sensor level to software.

LEVEL 3: THE INFORMATION IS PROCESSED/SENT

The information from level 1 or 2 is used to make calculations regarding efficiency, operating time and future maintenance with the help of software that compiles the information. From here, you can also control and configure your devices further down the chain.

LEVEL 2: INFORMATION COLLECTED

Information is collected with the help of a master. For example, a PLC can be placed in the industry; this means that you do not have to configure your long wiring to the machine level. You can also configure the sensors remotely, so you don't have to go out to the site to adjust the settings.

LEVEL 1: SENSORS

Smart sensors in the industry communicate information to level 3 efficiently, thanks to IO-Link. The sensors can also be configured remotely, making the products ‘Smart’.

5 ADVANTAGES OF IO-LINK

- IO-link allows you to collect information from your sensors and enables you to configure them remotely.

- During maintenance, it is easy to time-efficiently replace the product with the same settings as the replaced product

- You want to avoid unplanned downtime and, once you plan to stop production, you want the opportunity to replace several products at the same time

- With the help of IO-link, you can see the status of your products. In addition, the simplicity of IO-link means that fewer errors occur when the system is connected

- Thanks to the IO-link interface, all products can collaborate, regardless of brand, saving time and resources on integration and translations between different protocols.

IO-LINK AT OEM AUTOMATIC

“At OEM Automatic, you will find a wide range of different IO-Link products, cutting-edge knowledge in different areas and a partner who has a great understanding of integration,” concludes the company. “In addition to knowledge, we also have a great interest in developing the industry and want to offer you the best products for you and your process.

“We collaborate with partners that add a lot of knowledge and experience with integration, which is about connecting different smart products that can deliver information. You also want to manage this information to benefit your process and configure your products.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>