Posted to News on 21st Apr 2011, 16:48

All-electric road car uses slimline hybrid bearings

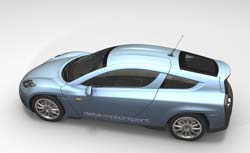

Schaeffler has developed specialised hybrid bearings with very compact dimensions for use in innovative motors for the Delta E-4 Coupe all-electric road car.

Innovative hybrid bearing technology from Schaeffler UK has enabled engineering consultancy and electric vehicle manufacturer Delta Motorsport to design and build from scratch an all-electric road car that is capable of accelerating from 0-60mph in less than five seconds and achieving a top speed in excess of 150mph.

The Delta E-4 Coupe is a four-seater, two-door coupe that boasts a class-leading range of more than 200 miles on a single charge. The vehicle can accommodate four adults, but its acceleration is claimed to be comparable to that of a Porsche 911 Turbo.

Key to the E-4 Coupe's impressive performance is the high-performance direct-drive electric motor that powers the car. Designed in partnership with Oxford University and Oxford Yasa Motors to meet Delta Motorsport's performance requirements, the new design of axial-flux electric motor generates well over 600Nm of torque while only weighing 23kg.

Hybrid double-row angular contact ball bearings

This was the breakthrough that Delta Motorsport needed if the Company was to fulfil its ambition of developing a high-efficiency plug-in battery electric 'car for the people' that is both stylish in its design and financially viable - and also capable of overcoming the 'range anxiety' perceived by many purchasers of all-electric vehicles.

Stewart Davies, a Senior Applications Engineer at Schaeffler UK, says: "It was a very interesting project to work on, with very demanding criteria to meet. The challenge was to keep the bearing as narrow as possible in order to meet the dimensional constraints of the design envelope inside the YASA motor, whilst at the same time offering a commercially viable bearing solution within a very tight timescale."

Schaeffler UK was able to supply the first samples four months after it started work on the project. Davies continues: "The initial bearing design concept proved to be too expensive and threatened to jeopardise the project. Following intensive design calculations, we were able to offer a single hybrid bearing that met the key design criteria of high performance, reliability and ease of assembly but that could also be competitively produced in volume."

Non-contact shields

One of the problems encountered by Schaeffler's design team was the high seal lip speed. With the bearing rotating at such high speeds, all calculations indicated that the seal would wear out and that the bearing would fail prematurely. However, specifying a non-contact shield solved this problem. Another advantage of using a non-contact shield is the increased life expectancy of the grease. Davies explains: "A hybrid bearing has all the insulation qualities required for use in electric motors, including low friction, but the non-contact shield has doubled the life expectancy of the grease, which has further enhanced the performance of the bearing."

Dr Tim Woolmer, whose DPhil at Oxford University led to the creation of the YASA motor, adds: "The partnership with Delta and Schaeffler helped us to create performance prototypes of the motors very quickly. The design has proven to be so robust at high-torque and high-speed conditions that Oxford YASA Motors have adopted it as part of the next-generation design being finalised for higher-volume production."

Delta Motorsport is used to overcoming many challenging engineering problems, having been involved in a wide variety of concept, design and prototype project work ranging from sports cars and motorcycle safety products, to hybrid and battery electric vehicles. It is the company's work in top-level motor sport - where vehicle weight, aerodynamics and mechanical efficiency are key success factors - that has enabled Delta to optimise the performance and handling of the E-4 Coupe.

Carpenter states: "Problem solving is in our DNA. However, designing a road car is a very different challenge to designing a racing car. It is not that any one task is particularly complex but simply the sheer number of challenges involved, from keeping the water out to making sure the car handles well."

Energy efficiency

Delta Motorsport is keen to focus on reducing all cars' energy consumption and makes a clear distinction between low-emissions and low-energy vehicles. Simply converting a high-performance car to batteries would turn it into a low-emissions vehicle but would not necessarily reduce energy consumption.

Carpenter's enthusiasm for the E-4 Coupe and the future of sustainable vehicle technology is inspirational. "We have learnt so much just by rolling our sleeves up and having a go. With the motorsport industry firmly based in the UK, the culture of innovation is our breeding. There is a great opportunity in this sector for UK plc, and Delta is looking forward to taking this 'Philosophy Transfer' to the next stage."

The company's sights are also set on record attempts such as the electric land speed record (currently just over 300mph), and ultimately the 'Holy Grail' is to be the first wheel-driven car over 500mph.

Carpenter concludes: "Schaeffler's bearing know-how has been an enabling factor in Delta developing this class-leading product. We would not be where we are now without it."

For more information on Schaeffler's range of bearings and engine components for hybrid and all-electric vehicles, go to www.schaeffler.co.uk or telephone the marketing department on +44 (0)121 313 5870 and request a copy of the HEV1210 brochure.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>