Posted to News on 14th Sep 2016, 17:57

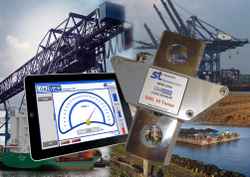

Automatic monitoring of mobile harbour equipment

The increasing globalisation of the world economy is pressurising ports, docks and harbours into handling ever-increasing volumes of cargo, so mobile harbour equipment has to work efficiently and reliably at all times. Tony Ingham of Sensor Technology Ltd explains how monitoring the work rate of cranes, loaders and unloaders means their performance can be optimised and downtime for maintenance can be scheduled for minimum disruption to operational requirements.

Importing and exporting of dry bulk cargos, from minerals to grains, fertilisers to cement, wood chips to agricultural products, is almost exclusively a maritime operation. Thus there is a need to load and unload ships and barges, and in the modern world this has to be done quickly, efficiently and safely.

So as the volume requirements of world trade increase, harbour operators must ensure their loading/unloading equipment is in top condition, always available for use, and able to adapt to new operational, commercial and safety requirements.

The best way to maintain such equipment is constant monitoring while it is working. This will allow the work to be totalised so that pre-emptive maintenance scheduling can be optimised, and will also instantly pick up early signs of emerging problems, such as sticking bearings.

The work done is directly related to the totalised load lifted, a parameter that crane and loader operators should also be measuring for both safety and commercial reasons.

Constant load monitoring used to be very difficult, but Sensor Technology has developed LoadSense. It was originally used with helicopters carrying underslung loads in cargo nets and has now been adapted for use on ground-based materials handling equipment.

The technology involves a sensor being fitted to each crane or unloader. Once installed this does not interfere with handling operations at all, but constantly sends real-time data via a wireless link to a computer, where it can be displayed, stored, totalised and analysed to provide performance information to the operators and billing information for the customers.

LoadSense is an intelligent load sensor that can easily be integrated with a mobile harbour crane. Designed and manufactured by Sensor Technology in Banbury UK, it is fully automatic so causes no disruption to normal operations. Special training is not required; instead comprehensive and easily understood information becomes instantly available to operators and managers alike.

Strain gauge technology

The LoadSense sensor is based on proven strain gauge technology, and is calibrated as standard in the range 1-50 tonnes, with other ranges available on request. It constantly monitors the load and transmits this wirelessly, using the unrestricted 2.4GHz waveband, to a receiver for onwards transfer to the control computer. This enables accurate load data to be displayed, typically via a colour touchscreen computer, running Windows XP. The screen shows real-time measurement of the load, while the computer records and analyses it.

LoadSense has become a favourite amongst harbour crane operators as an important enabling technology to improve safety, asset availability, productivity and profitability. For instance, you may need to know how much material you have transported, or you could be handling two or more materials simultaneously which need to be accounted for individually. A common scenario is where multiple customers' cargos are being handled at the same time; here LoadSense gives operators the information they need in order to invoice each appropriately.

LoadSense also enhances safety and prevents dockside handling equipment from failing catastrophically. There are typically two reasons for such failures:

- Overloading the crane with too much weight. Because LoadSense is constantly producing a digital signal, it is easy to set up the control computer with an overload value that will trigger an alarm if it is breached. It is equally simple, and practically better, to set the computer so that it will cut out lifting operations if the overload limit is breached, thus ensuring excessive loads are not raised off the ground.

- Aging cranes and unloaders can suffer fatigue failure. LoadSense can be used to keep count of the number of operational cycles performed, and signal when the equipment's design life is being approached. An inspection can then be conducted to determine the likelihood of imminent failure and remedial works that can be undertaken.

In conclusion, we can say that to be profitable harbour operators need to work their dockside handling equipment long and hard and that the best way to ensure reliability and safety is by constantly monitoring the load and interpretation of the ensuing data. LoadSense from Sensor Technology makes this requirement completely automatic and foolproof.

For more information about LoadSense from Sensor Technology please visit www.sensors.co.uk.

Apollo Park, Ironstone Lane

Wroxton

OX15 6AY

UNITED KINGDOM

+44 (0)1869 238400