Posted to News on 14th Oct 2019, 10:09

Automation and drive technologies control cabaret stage movement

With the help of KEB Automation, the most famous cabaret in the world has modernised its stage technology to suit the new programme "Le Lido Spectacle Paris Merveilles'. Founded in 1946 and located in the Avenue des Champs Elys©es in Paris, the LIDO theatre is using modern automation and drives technology from KEB, which controls the movements of the new stage settings.

French company COMETE was awarded the overall contract and subsequently spent the next 15 months planning the project and developing the new automation and control concept. An essential part of this new automation concept is the electronic drive and control technology from KEB.

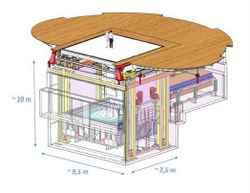

The technical application definition for KEB was as follows: a hoisting gear with a load capacity of 110 tonnes presents to the audience, depending on the stage situation, an 80m3 pool, a 50m2 ice surface or two other stage settings. As another variant, a mobile ground floor of 190m2 is used that provides space for 410 visitors and tables.

The centrepiece of the automation concept is the powerful KEB Combicontrol Compact II embedded control system and the "Yaw Library' with software components for the coordination of loads on distributed drives. The flexibility of the hardware and software of Compact II is another important element in the overall system for the stage technology, where super-ordinated master computers communicate serially with CAN-Bus and, on the other side, the actual motion profiles of the drive axes are controlled in real time via the EtherCAT protocol in synchronous communication. The KEB Combivert F5 drive controllers are universally suitable for the operation of different motors and possess the integrated safety function STO according to IEC 62061 - SIL3.

With fundamentals gained from the torque-sharing methods used in offshore wind turbines, it was possible to design and implement a powerful stage system within a short time. The high quality of the torque control and precise positioning of different elements on hoisting and running gear will ensure over the coming years an active stage setting full of motion in the cabaret.

For more information on the Combivert F5 or the Combicontrol Compact II go to www.keb.co.uk.