Posted to News on 3rd Oct 2022, 10:35

Cabling accessories are indispensable for enclosures

Systems accessories for cabling are key to many enclosure installations, but it is important that that these accessories meet the same requirements as those that apply to building the panel, as Emma Ryde, Rittal product manager for industrial and outdoor enclosures, explains.

Protecting critical equipment is a key role of any enclosure installation, ensuring the switch and control panels protect electrical devices in hostile environments. They prevent damage from moisture, dust or contact. But that is not enough. Accessories are often used for ease of use and to make the assembly of panels simpler and clearer. These usually originate from the user. It is important

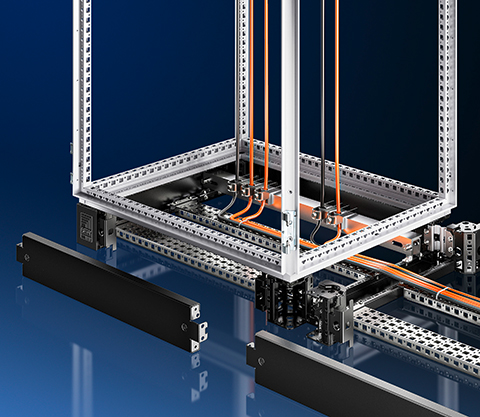

Various materials are available for Rittal’s VX25 add-on unit series to keep electrical and pneumatic components separate from each other. Think of rail systems, mounting profiles, system chassis and mounting rails.

Non-electrical parts and appliances that do not belong directly to the electrical equipment cannot simply be placed within the housing containing the switchgear. Solenoid valves must therefore be kept separate from other electrical components by placing them in a separate compartment made with rail systems.

System chassis, which are used in the door of the VX25 to make optimal use of cabinet space, can sometimes also be used for the AX wall and floor cabinet series. The same applies to different mounting profiles.

Cable routing at moving parts is a key consideration. The IEC standard states that “connections to appliances mounted on doors or other moving parts are made using flexible current conductors (…), allowing regular movement of the part”. Pipes must be secured to the fixed and moving part.

Because cable hose holders have the same hole pattern as the cabinet frame of the VX25, the door profile in the AX, as well as the mounting rail and system chassis, they can be mounted there easily and quickly. The plastic cable hose makes it easy to establish a reliable connection with flexible current conductors. This also fulfils the requirement that “sufficient mechanical strength must be provided, without compromising proper functioning”.

Cable entry and IP class

In addition to cable routing, the cable entry into a switch and control panel is also important. Maintaining the IP protection class is paramount. The IP value says something about how well a cabinet can keep out threats such as dust and water. The latest standard does not allow openings in the enclosure (such as those for the passage of cables) to impair the degree of protection.

At the same time, openings for on-site cable entry must be easy to open again. The VX25 wall cabinet has sliding metal bottom plates, which create an opening for cables. Additional provisions are therefore required for correct and safe cable entry. An elastic clamping profile seals the opening. This creates a flexible cable entry that guarantees that the issued protection class remains intact. Variants that can be made on this: a profile for cable entry between bottom plates (symmetrical) or between enclosure frame and bottom plates (rear).

Cable glands, modular cable glands or connector glands are also used for the AX wall and floor cabinets. The basic requirement is the same: maintaining the protection class.

For machines with cable tray systems it is advisable to apply additional edge protection over the parts where cables are pulled with a plastic protective edge, grommet or rounding. Simply deburring sheet metal edges is often not sufficient to prevent damage to the sheaths of lead-through cables.

The bottom plates of the VX25 are double-folded and have a rounded edge. This prevents a cable from being damaged when being fed-in from below. In addition, these plates are extra sturdy and resistant to bending, making a substantial contribution to the protection class.

Cable support and rails

Finally, attention must be paid to the connections of cables. They must be sufficiently supported to prevent mechanical stress on the connections of current conductors. A frequently used method is to fix the cables with cable clamps. These are available in different designs and sizes, which allows the use of a universal profile.

Also consider the slide rail for the mounting plate with the VX25 extension unit. When the plate is in its final position, these rails are – in principle – unnecessary. Nevertheless, due to the C-shape of the system chassis, they can be used for cable fixation with clamps for C-rails. These cable clamps are of course provided with a plastic part, to protect the cables from damage.

Cable fixings can also be placed in mounting rails. Cable ties are very useful for quickly securing cables to system chassis, mounting rails and profiles to the cabinet frame of the VX25. These cable ties are easy to press into the round system bore, after which it is a matter of bending and securing the cable. The cable tie is also suitable for securing cables in the cable hose holder.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Braithwell Way, Hellaby Industrial Estate

Hellaby

S66 8QY

UNITED KINGDOM

+44 (0)1709 704000