Posted to News on 6th Jun 2022, 12:00

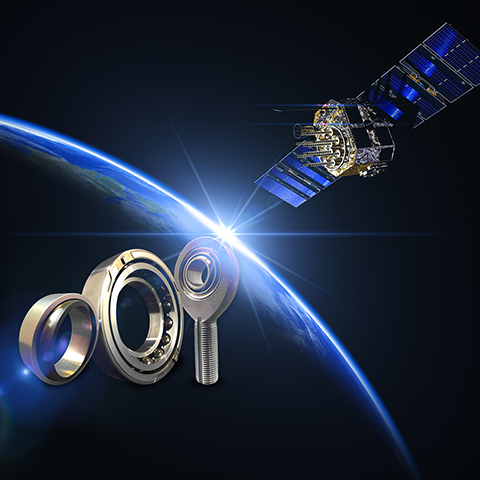

Carter Bearings ‘space heritage’ on show at Farnborough

The 2022 Farnborough Air Show provides precision bearing specialist Carter Manufacturing with the ideal opportunity to showcase its technical expertise in supplying specialist aerospace bearings and aerospace bearing tool services on Stand 1031.

Carter benefits from the all-important status of ‘Space Heritage’ having had direct involvement in providing complete design and engineering support for prestigious ESA and NASA applications.

From critical space to commercial aerospace applications Carter can provide precision bearings which are AS9120B and EN ISO9001:2015 certified including; hybrid, thin section, spherical plain and miniature, which are LNG, LOX, CH, LH2 and LN2 compatible. The company’s tooling services include: install and remove, swage, proof load and torque test along with custom tools and kits.

Carter also offers a range of completely controllable UNASIS aerospace bearing heaters, specifically designed to meet the exacting demands of the aerospace sector for a wide range of bearing sizes with an OD of 25mm up to 600mm and weights from juts 100g up to 600kg.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 7 Isis Court, Wyndyke Furlong

Abingdon Business Park

OX14 1DZ

UNITED KINGDOM

+44 (0)1865 821720