Posted to News on 10th Mar 2023, 12:00

Choosing the right modular safety system

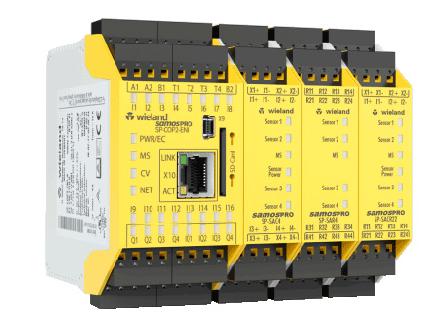

Modular safety systems can deliver significant benefits, as long as key features are included in the specification, as the experts at Wieland Electric explain.

When a risk assessment is carried out to identify appropriate safety features for complex machines, it makes a lot of sense to investigate which technologies will underpin straightforward and cost-effective compliance. That’s why there has been growing recognition of the benefits of modular, configurable safety controls in the last few years.

For example, a key benefit of a modular system is that it allows the complexity of the wiring to be reduced, compared to using stand-alone safety relays. This is because standalone safety relays need to interact with each other, which can require very complex wiring, so that design time, installation and commissioning are often extended.

In reducing complexity through such a design approach, there is the potential to significantly reduce the overall life-cycle costs of a machine safety system. Of course, this has to be achieved without compromising on safety – that’s a given.

Modular, configurable safety control systems provide a very clear illustration, as required by EN13894-1. They then use centralised input/output (I/O) systems that reduce the hard wiring requirement and therefore the overall complexity. However, the complexity of the wiring can vary considerably between different types of modular safety systems – so choosing the right one is important.

Which modular system?

Currently, there are two types of modular solution to choose from – mechanically configurable systems and software-based safety circuits. Mechanically configurable options tend to have more complex wiring, so utilising a software system with a centralised I/O will be the preferred option in most situations.

However, there is also variation in the level of complexity between different types of software-based systems, particularly in terms of the complexity of the wiring requirements for monitoring many of the faults that may occur.

Some systems have a fixed number of I/Os, so it may then be necessary to pay more for a system when additional I/O blocks are required. This can be a particular problem for smaller systems, resulting in paying for more I/Os than are actually required, often making the use of a modular system financially unviable.

In contrast, other solutions offer the controller separately from the I/O module, which makes it very easy to match the I/O requirement precisely to the requirements of the system – typically making for a more cost-effective solution.

Network communications

In most modern systems there is a need for communication with a wider network which, if stand-alone relays are being used, will require additional contacts for feedback. This can be avoided by using a software version that offers a common protocol. Also, a controller that can send diagnostic information through these gateways will ensure faster and more accurate fault detection.

There are also benefits to automatic date and time stamping of full reports, in terms of both meeting legislation and making it easier to identify the root cause of the fault.

When using a software-based system it is useful to include a self-validating verification process as required in EN13849-1 and EN13849-2, as this will prevent mistakes being made and ensure compliance with appropriate regulations. These can also be date and time stamp verified. Without this functionality, a considerable amount of time is required for producing the written reports, diagrams and photographs necessary for system verification.

Software costs

Another consideration is the cost of the software itself. Some licence fees only cover basic functionality, with additional charges for extra functions, such as burner control, press functions or motion systems. At the other end of the spectrum, companies such as our own make the software freely downloadable with all of the functionality included as standard.

When considering modular safety systems then, it is important to address all of these criteria to ensure all of the potential financial and performance benefits are achieved. Researching the various solutions at the beginning of the project will pay dividends in the longer term and assist with the documentation for current standards and legislations.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Ash House, Tanshire Park

Shackleford Road

GU8 6LB

UNITED KINGDOM

+44 (0)1483 531213