Posted to News on 3rd Oct 2022, 12:00

Close coupling of hydraulic pumps directly to the prime mover

Getting the most out of your machinery often depends on close integration between all components, with the correct specification of couplings between them to ensure proper shaft alignment, optimise performance and minimise wear. The experts at jbj Techniques guide us through the design considerations for hydraulic adapters to couple hydraulic pumps to prime movers.

In application areas as diverse as industrial, mobile, marine, machine tools, agricultural equipment and offshore installations, machinery that needs to generate high forces in a compact package will typically rely on hydraulic drive systems. At the heart of that power transmission system is the hydraulic pump, in turn driven by a prime mover which might be a motor (electric, hydraulic or air) or an engine.

Correct coupling of the hydraulic pump to the prime mover is key to the performance of the entire drive system. Improper pump installation can lead to premature pump failure, increased maintenance costs and reduced productivity. And correct pump shaft alignment is required to prevent unnecessary wear and damage to the pump shaft seal and bearing.

Also to be considered are unwanted torsional resonant frequencies in the system which can quickly cause damage to components in the drivetrain, reducing system life and again impacting on performance.

Hydraulic pump adapters are specially designed to provide close coupling between the pump and the prime mover, ensuring optimised performance of the drive system, minimised wear, reduced maintenance performance and long service life.

Because the overall system design – from pumps and motors to gearboxes, clutches, couplings, bellhousings, flanges, seals, coolers and more – and the specific performance requirements are different for every system, jbj Techniques does not rely simply on a catalogue of off-the-shelf components, but also manufactures and integrates all of the diverse components of a drivetrain to provide a tailored solution. These means the perfect system can be built from an extensive range of components available from stock, or can be manufactured to order.

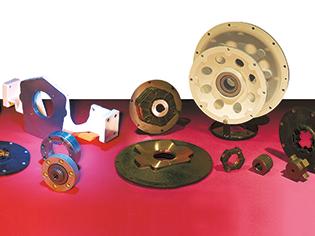

Within this capability, jbj Techniques manufactures bespoke hydraulic adapters. Each consists of a bellhousing and flexible drive coupling that are fully machined to suit the driving and driven components. These can be to suit either shaft to shaft, flange (flywheel) to shaft or even flange to flange connections.

For connecting the hydraulic pump to an electric motor, jbj’s comprehensive range of bellhousings can accommodate motors with IEC frame sizes from D56 to D400 (0.06-750kW) and can be compatible with electric motor B5 or B14 flange configurations. There is also a complete range of mountings to suit NEMA and imperial frame motors with C face or D flange fitments.

Bellhousings can be manufactured in aluminium or cast iron material as standard, while a variety of exotic materials can be accommodated on request. The aluminium product range is produced in either monoblock or composite formats giving great flexibility in design and allowing for early delivery time – often with same or next day delivery possibilities.

With fully machined, torsionally flexible or torsionally rigid couplings available, jbj ensures the most suitable combination is selected for the application. The spider couplings are available in various materials including aluminium, grey cast iron, nodular iron, steel and stainless steels, and can be finish machined with parallel, taper or splined bores to DIN, SAE, ANSI or ISO standards.

For applications where low noise levels are a requirement then a complete range of anti-vibration and noise reduction components add to the range.

Hazardous areas

Hydraulic adapters can also be manufactured to couple pumps to electric motors in hazardous area applications, meeting ATEX standards. Couplings supplied for these applications provide an anti-static and flameproof drive which meet zone 1 area requirements, conforming to all of the above standards. Also available are spider and gear couplings which are certified to zone 2 standards.

An area of coupling specification in hazardous area applications that needs to be considered is possible high temperatures generated by a piston pump shaft seal when the pump is cycling between different pressures. This process will often take the seal temperature beyond the levels required by the relevant ATEX standards.

To address this issue jbj Techniques offers the wet mount series of bellhousings. This specially designed assembly allows a pumped cooling flow to be passed over the seal face and through an auxiliary cooler. This in turn reduces the seal face temperature which can be maintained at an acceptable level.

Adapters for engines

In addition to hydraulic adapters for electric motors, jbj Techniques is also able to provide a complete range of bellhousings and couplings for both petrol and diesel engines. Diesel engine dimensions from SAE 6 to SAE 0 can be accommodated, and couplings to complete the assembly are available in either torsionally flexible or torsionally rigid design.

For hydraulic pumps to be mounted to engines that do not conform to SAE dimensions, JBJ offers a full range of assembly parts. All bellhousings within this range can be finished machined to accept any piston, vane or gear pump interfaces.

As with the electric motor range of hydraulic adapters, jbj Techniques offers complete solutions for ATEX environments.

For petrol engines, adaptors have been developed to suit Honda, Briggs and Stratton, Kawasaki, Kubota, Hatz, Mag, Robin, Suzuki and Winsconsin engines, to name but a few. All adaptors can be finished to accept most hydraulic pumps. Adaptors to suit engine crankshaft drives and for vertical mounting are available on request.

For all of its hydraulic adapters, jbj’s in-house design team and manufacturing facility provide tailored solutions for customer applications at competitive pricing and with on-time deliveries. jbj Techniques can advise on the correct installation of hydraulic pumps the application and can specify complete driveline systems from its extensive range of components – available from stock or manufactured to order, whether simple or complex, standard or bespoke.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

28 Trowers Way

Holmethorpe Industrial Estate

RH1 2LW

UNITED KINGDOM

+44 (0)1737 767493