Posted to News on 30th Jun 2025, 17:00

Compact long-range time-of-flight sensor for precise distance measurement

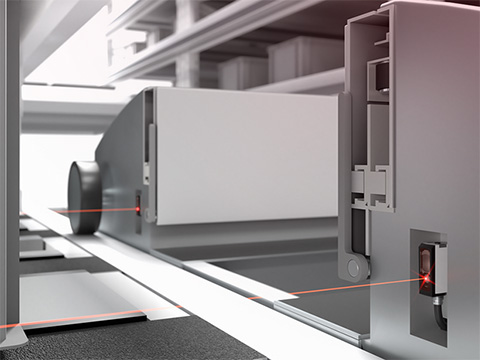

SensoPart is expanding its family of miniature sensors with the launch of the new FT 25-RLAP time-of-flight sensor, combining precise distance measurement up to 1.5 metres with a compact, space-saving design.

Built for demanding industrial environments, the FT 25-RLAP offers a powerful set of features including analogue output, IO-Link communication, and exceptional background suppression - all in a housing measuring just 34 x 20 x 12 mm.

Precision even in challenging environments

Using proven time-of-flight (ToF) technology, the FT 25-RLAP accurately measures distances regardless of the object's shape, colour, or surface finish. Even reflective vests, flashing signal lights, or shiny metal backgrounds won't interfere with its performance. The result is consistent, reliable measurement data that enhances process stability in automation systems.

The FT 25-RLAP includes both an analogue output and a switching output, which can be configured independently using the integrated pushbutton. The analogue output is scalable between 1-10 V using two teach points, while advanced setup and diagnostics are available through the latest IO-Link specification (v1.1.4).

Other smart features include window mode to mask out irrelevant distance ranges, and offset teach to set new reference points for quick reconfiguration. These functions make the FT 25-RLAP a highly adaptable solution for changing application needs.

Compact design, easy integration

SensoPart has successfully packed advanced time-of-flight technology into an ultra-compact housing - measuring just 34 x 20 x 12 mm. This miniature size makes it easy to install the sensor in tight spaces or compact machine layouts. A clearly visible, high-precision light spot simplifies alignment during setup, while its Class 1 laser rating ensures safe operation without the need for additional protective measures.

Alongside its analogue and switching outputs, the FT 25-RLAP features an IO-Link interface compliant with the latest 1.1.4 specification. This ensures seamless integration into today's automation environments and unlocks advanced configuration, diagnostics, and monitoring capabilities - supporting smarter process control and predictive maintenance.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>