Posted to News on 13th Jul 2022, 16:41

Contrinex’s pressure rated inductives pack a punch

When an automotive manufacturer needed robust, high pressure inductive sensors for use in its punch-riveting in their prototyping area, it turned to Contrinex.

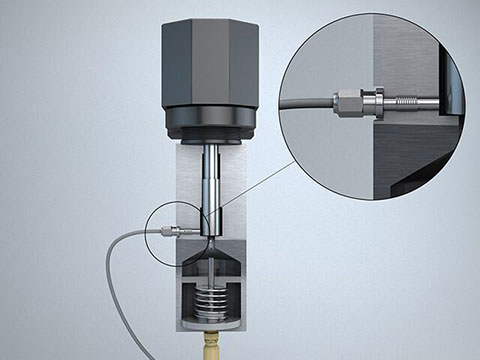

Cold-forming is a popular low-cost method for joining sheet metal using a punch-riveting press. To ensure reliable and fast bonding, a high-pressure rated Contrinex inductive sensor is trusted to control the press. The inductive sensor is mounted directly in the wall of a small pneumo-hydraulic cylinder where it detects the hydraulic ram’s position to ensure that the operating cycle only starts when the ram is fully retracted.

Within the automotive manufacturer’s prototyping area, vehicle bodies are assembled using manual punch-riveting tools to join the individual sheet-metal parts. Several thousand joints are required per vehicle, and the tools must be small since space is often limited.

If the technician does not set the tool correctly, the resultant bad joint can be very costly to repair. The tool-head can often be partly hidden from view on some joints and so a sensing system was designed to ensure that the operating ram is fully retracted. It prevents the tool from operating if the ram is not in the correct position.

Whilst the small size of the press tool limits the sensor’s size, embedding it into the pneumo-hydraulic cylinder means that the sensing face is exposed to the high-pressure side of the hydraulic circuit. Contrinex’s boast is that its high-pressure inductive sensors work for 50 times longer under pressure than the market standard. They can withstand continuous pressures up to 500 bar (7,250 psi) and pressure spikes of 1000 bar (14,500 psi).

The robust inductive sensors from the Contrinex’s High-Pressure range easily withstand the high operating pressure of this application, offering world-class reliability. They also benefit from Contrinex’s patented Condist long-distance sensing technology, which allows the use of thick, hermetically sealed ceramic discs on the sensing face, without compromising the sensors’ performance.

These lightweight M5 and M8-diameter embeddable sensors are only 27 mm and 30 mm in length, respectively and therefore their mounting directly into the wall of the cylinder does not interfere with the normal operation of the tool. Their sensing distances of 1mm and 1.5 mm, eliminate the risk of internal mechanical damage through contact with the ram.

A picture containing kitchen

The sensors feature an industry-standard PNP normally-open output and a flexible PUR-sheathed cable. Their vacuum-encapsulated electronics ensure excellent resistance to shock and vibration, and no additional electrical or mechanical protection is required. They also feature the industry-standard IO-Link protocol, which ensures their best-in-class performance is coupled with ultimate ease of use, plug-and-play swap-out, and easy Industry 4.0 implementation, in even the most demanding circumstances.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>