Posted to News on 14th Sep 2023, 15:30

Contrinex’s RFID eliminates hose-coupling bulk-handling errors

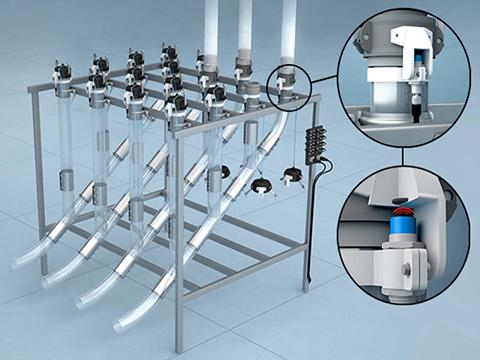

Bulk-handling hose-coupling stations are commonly used in food manufacturing plants to connect several material sources, typically silos or storage bins, to multiple processing machines, like mixers. Contrinex’s RFID technology is used to eliminate connection errors at the manual hose-coupling station.

A Contrinex IO-Link-enabled read/write module (RWM) is mounted beside the latching mechanism of each coupling to read RFID transponder tags on the input hoses. The RFID tags are mounted within each hose coupling and blanking cap to identify the mating parts uniquely - This allows the individual outlet/hose combinations to be verified at the time of connection.

Bulk handling of fluidisable materials across industries, including food processing, plastics and pharmaceuticals, commonly use pneumatic conveying systems to transport powders, granulates and other fluidisable materials. Pneumatic conveyors offer quick, reliable high-volume transportation with minimum degradation of the transported material.

Coupling stations offer a simple and cost-effective means of connecting several material sources, typically silos or storage bins, to multiple processing machines. A pipe from each source enters the bottom of the coupling station, where it branches, providing multiple outlets for each material. Quick-release hoses, connected manually to the corresponding outlets, feed materials to machines. To prevent contamination, unused outlets are capped.

Human error can result in hoses being connected to the wrong outlet, causing costly errors if undetected. Therefore, systems designers wanted to provide real-time confirmation that the correct hose has been connected to each outlet, or, where no connection is specified, that a blanking cap is in place. An industry-standard interface is highly desirable, but an expensive or ultra-high-speed communication protocol like ProfiNet is not essential.

IO-Link-enabled Read-Write modules (RWMs) and RFID tags from Contrinex proved ideal for this application. An IO-Link enabled RWM, mounted on each outlet pipe, is connected to a plant-wide control system via two low-cost industry-standard 8-way IO-Link master hubs.

An RFID tag, mounted integrally within each hose coupling, identifies the hose uniquely, allowing the outlet/hose combination to be verified at the time of connection. Blanking caps also carry unique RFID tags to confirm that unused outlets are closed with their cap.

The mechanical design of the mounting frames for the RWM and the transponder tags ensures that the coupling or cap can only be locked in place once the RFID elements are aligned. With data-transfer rates up to 38.4k baud, the sensors provide data in real time, triggering an immediate alarm in the event of a connection error. The system also provides an auditable history of what material inputs were connected to which machines.

Contrinex IO-Link RWMs are configurable to operate in one of two discrete modes: IO-Link mode allows remote communication via the standard protocol. If local, non-networked control is preferred, the ’standard I/O mode’ (SIO) allows the device to function as an intelligent, presence-sensing sensor. Process engineers can switch RWMs between modes either remotely, using the IO-Link protocol itself, or locally, using a pre-configured ‘Master’ RFID tag, which is simply placed on top of the RWM during the RWM startup process.

With sensing distances up to 60 mm, robust M18- and M30-threaded metal housings and integral M12 connectors, Contrinex RWMs are ideally suited to the environment of a busy industrial processing plant. They are compatible with all ISO/IEC 15693-approved RFID tags, allowing designers ultimate flexibility and excellent value for money.

Contrinex’s extensive RFID range also includes transponders designed to survive vibrations and shock, or high temperatures within harsh manufacturing environments, or transponders which can survive the aggressive cleaning chemicals of the food and beverage industry.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>