Posted to News on 12th Jul 2021, 08:58

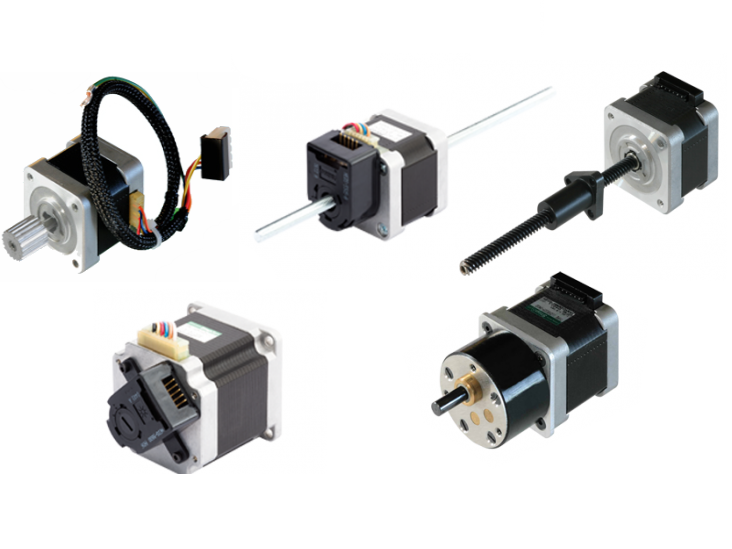

Customised stepper motors at the ready

Quick customisation and prototyping can simplify integration into equipment

EAO and Sanyo Denki offer a wide range of customisation options – from the fitting of encoders, the machining of motor shafts and addition of lead screws, to the fitting of dampers, brakes and special cable/connector harnesses.

“Quick customisation and prototyping are crucial for speed to market,” says EAO, “and with Sanyo Denki's European design centre and local sales engineers, expert advice is close at hand.”

The range on offer embraces:

Optical or capacitive encoders and custom motor/encoder adaptor plates

Standard 42mm motors, with lead screws and quick customisation for bespoke versions

Shaft modifications include: hollow shafts, machined flats, holes, pulleys and gear cutting

Cables with connectors and sleeving for fast, easy connections to end equipment

Decelerators or brakes to hold motor position when stopped and dampers for reduced vibration

High-precision low-backlash gearboxes.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>