Posted to News on 11th Aug 2022, 11:00

Cyanoacrylate adhesives offer ultimate instant bonding solutions

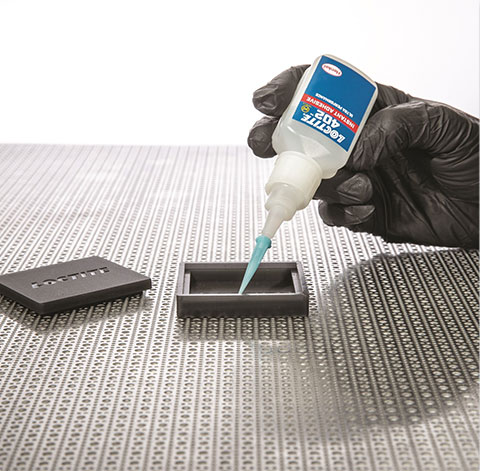

If you are looking to reduce overall manufacturing costs, increase product reliability, performance and operating life, Henkel says its Loctite cyanoacrylate adhesives (ie, instant adhesives) may be just the bonding solution for which you are searching.

For design engineers tasked with optimising product design and the associated manufacturing process, instant adhesives provide a fast, reliable alternative to traditional joining methods, such as mechanical fasteners and welding.

Designed for use in a wide variety of industrial applications, these adhesives are formulated to withstand impact and peel forces, provide high shear strength, and offer chemical and temperature resistance – and they do so in a matter of seconds. Let’s explore some of the ways Loctite instant adhesives can help improve your manufacturing to achieve a competitive advantage.

Fast fixture speeds

Instant adhesives reach fixture strength, or the strength where assemblies can be handled without falling apart, very quickly – typically in 5 to 20 seconds depending on the assembly. This rapid strength development translates to a reduction in work-in-process (WIP) and the ability to use a continuous flow assembly process.

A lighting manufacturer recently converted a traditional 2-part adhesive assembly operation to instant adhesives, reducing their time to handle parts from 8 hours to less than one minute. This not only increased their overall productivity but also opened available floor space where previously parts were staged for long cure times.

Fast fixture speeds plus reduced assembly time equals faster processing speeds and optimised production outputs, making Loctite instant adhesives ideally suited for automated assembly.

Superior bonding

Cyanoacrylates are single-component resins that polymerise or cure rapidly when exposed to alkali surfaces, such as water found in trace amounts on all surfaces. During this process, acidic stabilisers in the adhesive are neutralised and the cyanoacrylate hardens rapidly to form a rigid thermoplastic that adheres to almost any substrate.

The versatile bonding capabilities of instant adhesives are particularly useful for assembling products with a lot of small parts. In fact, the trend toward smaller and smaller consumer devices has spurred global market growth for instant adhesives of more than seven percent annually.

The versatility of instant adhesives is also conducive to applications that incorporate a variety of different materials, such as plastics, elastomers, and metals where some temperature or fluid resistance is required. This substrate versatility means designers have more choices in designing and assembling smaller, higher performing, and more aesthetically appealing devices.

Easier to automate

As manufacturers pursue faster, more cost-effective, and higher performance production methods, a variety of hurdles get in the way of component assembly. Existing adhesives and fastening methods for component assembly are slow, unreliable and can be difficult to automate. By contrast, Loctite instant adhesives are easy to dispense and apply via automated systems, making it possible to increase output and stream-line production.

Recently, an instant adhesive assembly solution employed by a loudspeaker manufacturer in replacement of a mechanical solution resulted in a 30% increase in productivity and the reduction in the number of operators required on the assembly line. Furthermore, instant adhesives require only a small dose to be extremely effective, which controls material costs, and enables new, simplified designs. All of that and reaching their full strength in 24 hours, often attaining shear strengths of 2,000 to 3,500 psi depending on the materials bonded.

Outstanding performance

Not only are Loctite industrial instant adhesives faster, more versatile, and easier to incorporate into automated production processes, but they also offer performance characteristics that will give you and your customers confidence in the long-term performance of your end device. There are specialty instant adhesives available that feature superior heat aging, hot strength, and high humidity resistance for reliable performance in the most extreme of conditions.

Toughness and impact resistance are additional features that aid in preventing failure of your product or device when in use. High-quality industrial adhesion and bonding materials are essential for any project.

Henkel has spent decades developing adhesive solutions that are trusted across the globe. Its team can recommend the perfect industrial instant adhesive that meets your requirements for strength, flexibility, environmental conditions, viscosity, sustainability, and more.

Download a white paper on this topic here

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>