Posted to News on 19th Jan 2023, 09:03

Delivering a tailored solution on time and on budget

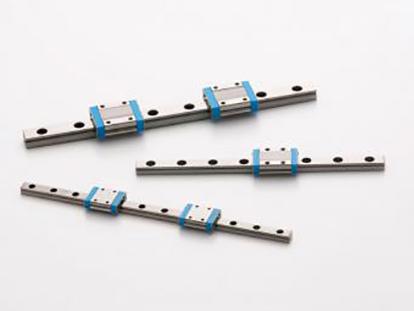

We talk to the experts at IKO Nippon Thompson about how linear rail and carriages can be easily adjusted and modified, and how projects can be re-designed around standard products, to save customers time and money.

A linear rail and carriage system is many a design engineer’s first choice for transporting a load, and for good reason. It provides a rugged and precise solution that is inherently self-aligning, offers high load handling capabilities, and can operate in some of the most challenging environments. But the temptation to over-engineer a system can add significant cost to a project, while asking a vendor to supply a non-standard arrangement can imply a lead time of months.

This is where IKO Nippon Thomspon’s in-house design and adjustments service becomes invaluable, with the UK team of applications engineers able to suggest design amendments that can reduce lead times from months to days, and/or remove significant cost from a project. Mark Ross, technical sales engineer at the company’s Milton Keynes UK headquarters, says: “There are a wide range of things we can do at local level, from the everyday to the more unusual, to deliver an application-specific solution, providing a key service that can save UK customers time and money.”

A prime example is the company’s ability to assess the key parameters in a project, and look at what can be easily amended without compromising the performance criteria, so that the project can be serviced from the company’s free stock. “For any supplier, manufacturing a system to order is going to take time, but IKO Nippon Thompson will always have standard products available as free stock at our various global locations, and we can tap into that free stock and have it delivered within a couple of days,” says Mark. “From there we have the in-house capabilities to modify standard products to meet specific customer requirements.”

Examples include cutting rail to specific length at the simplest level, or changing the e-dimension – the measure from the end of the rail to the first mounting hole. “As standard, this e-dimension would be half the normal hole pitch, but that might not suit the application,” Mark explains. “We can drill a new hole as required.”

Such adjustments and amendments can be important time savers for customers, particularly when they are building a prototype as proof of concept. But IKO Nippon Thompson’s design services can also customers significant amounts of money, for example when it is clear that the design engineer has over-specified the project, perhaps as a belt and braces approach to meeting particular lifespan requirements.

“We can quickly drill down to the customer’s most important considerations and then look at how that impacts on the rail and carriage dimensions,” says Mark. “By talking through load and stroke requirements, that might lead us to propose alternative carriage lengths. For example, has the designer opted for a shorter carriage to increase stroke length, but then bumped up the rail and carriage dimensions to accommodate the required load? Perhaps they’ve even ended up with a design that uses non-standard length carriages.

“By adjusting the rail and carriage dimensions, we can often find a much more cost-effective approach, selecting more appropriate and standard products or better cost products,” he continues. “We can play with parameters such as pre-load to see if this provides a better way to meet specific application criteria. Or we can butt together standard rails to deliver longer, non-standard lengths at given profile dimensions without impacting precision.”

There is more, too. Linear rail is inherently robust, but even so there can be a temptation to over-engineer a system to cope with challenging environments. “This will invariably do the job, but at what cost?” asks Mark. “A better approach might be to add seals and scrapers to protect the rolling elements. We can also offer different coatings, for example to protect against rust. All of these can ensure longevity of the system without the need to over-engineer, delivering significant cost savings for customers.”

All of this comes hand in hand with the capability to provide CAD drawings and models, and to port those designs straight into customers’ models.

IKO Nippon Thompson is conscious, too, of the cost of logistics for its customers, and so can supply pre-packaged sets to reduce packaging, handling and stock management. And then there is the company’s on-site training in addition to its telephone and web video support.

“It’s all part of a service that means we are much more hands-on with our customers than perhaps other suppliers are willing or able to be,” concludes Mark. “We want to be more involved because it benefits all of us – we get to deliver the most appropriate solution and customers get time- and cost-saving benefits.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

IKO Nippon Thompson Europe B.V.

2 Vincent Avenue

Crownhill

MK8 0AB

UNITED KINGDOM

+44 (0)1908 566144