Posted to News on 24th Sep 2018, 16:17

Demo machine to be unveiled at Robotics & Automation

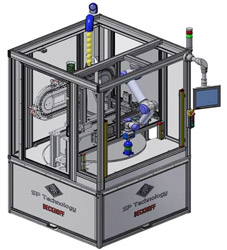

SP Technology will provide visitors to Robotics & Automation 2018 with a showcase of what can be incorporated into new automation systems. Typically SP Technology creates systems to overcome hurdles faced by clients such as assembly, testing, packaging, filling, and labelling.

Partnering with Beckhoff, SP Technology will exhibit a demo machine that shows how Industry 4.0 and machine monitoring can help in planning production. For example, the demo machine illustrates how systems can monitor changes in machine component power usage, vibration and overall efficiency, thereby enabling production targets to be met.

The company says that having the ability to see and monitor particular parts of a machines enables users to improve production by implementing preventative maintenance procedures. This is more than just stopping production every couple of months for a general health check; it is about having the ability to monitor the machine, its components and how they are performing in real time. By monitoring servo drives and index systems, for example, it is possible to identify if there is a particular one causing an issue, so the true mean time between failures (MTBF) can be predicted more accurately.

SP Technology recently had a customer in high-volume manufacturing that was able to reduce its PM by around 25 per cent by monitoring their machines in this way. Looking at live data and changes in the system enabled them to schedule maintenance when it was required.

Collaborative robots

As part of the demo machine, SP Technology has also integrated a collaborative robot (cobot) to show that these relatively newcomers to the market are not just for working next to humans, they can also be fully integrated within machines. This will demonstrate how cobots can function as normal when guarded but also how they can still interact with humans in a safe manner when outside of any guarding.

Although the machine on show is purely a demo unit, it provides an insight into how SP Technology builds machines and, just as important, how this will operate on a customer's shop floor. From fully self-diagnosing machine faults to simple work instruction on the HMI, SP Technology hopes to open everyone's eyes to Industry 4.0.

Follow the link for more information about SP Technology's bespoke automation services: www.sptechnology.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>