Posted to News on 15th Mar 2023, 13:00

Detecting cable stress earlier and more accurately saves costs

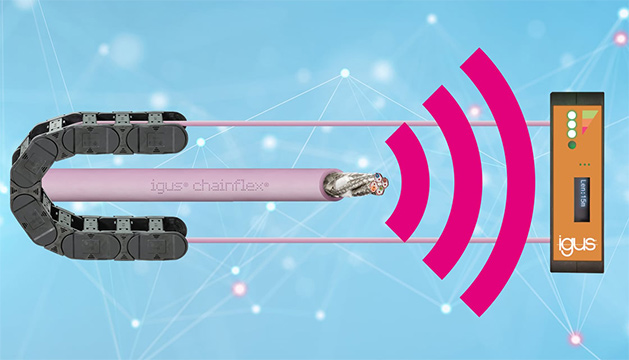

Maintaining and monitoring heavily used and hard-to-reach bus cables is a constant challenge. i.Sense CF.D – the monitoring module from Igus – has a unique function; it automatically detects the position of stressed areas in a cable and displays the length of cable where the defect is recorded.

The new, visual status display means that users can now intervene quickly and more accurately, thus avoiding time-consuming and costly troubleshooting.

Imagine it’s Monday morning in a busy automotive plant, and a robot is welding checked parts. Thanks to its 7th axis, the robot moves in a large workspace and is supplied with data via Ethernet cables. An operator opens the control cabinet of the welding robot and wants to know if all Ethernet functions are working properly. One look at the coloured signal lights of the monitoring module i.Sense CF.D shows that the transmission quality is weak in one cable.

Three different Ethernet types are used on the robot: a static cable from the control cabinet to the e-chain of the 7th axis, a chainflex bus connection in the e-chain system, and a chainflex robot cable for torsion movement on the robot. External influences can affect the transmission quality, but the cables are very long and difficult to reach in many places.

“In such cases, searching for and correcting errors is often tedious and costly,” says Justin Leonard, director of e-chains and cables at Igus UK. “So we have developed a new function for the i.Sense CF.D monitoring module, that we believe is unique worldwide: an visual status display that indicates the precise distance of the suspected fault location.”

i.Sense CF.D continuously measures transmission characteristics as well as various electrical parameters over millions of cycles. Therefore, the system not only detects data loss in real-time, but also identifies the position of the cable’s stressed area very accurately.

“With this information, which appears directly on the OLED display of the module, users can identify the risk area more accurately and faster than before and immediately replace the management of the corresponding cable section without laborious trial and error, and without additional tools or software costs,” says Leonard.

Installing the i.Sense CF.D module is just as quick. Users simply install the module in the control cabinet and plug the cables to be monitored into the module, then they can start immediately.

It is just as easy to extend the system with the multifunction i.Cee module. This smart module is compact, taking up very little space in cabinets and, just like i.Sense CF.D, gets to work in a few simple steps. i.Cee enables automatic cable monitoring, fault management and predictive maintenance planning via digital control. All the live parameters of the cables – such as the number of strokes and mileage in kilometres – are recorded and displayed on a dashboard. Usually, technicians have only two options for the maintenance of heavily mechanically stressed cables: either they react, ie replace cables when a defect has been detected, but this often means unnecessarily long and expensive downtime. Or they replace cables as a precaution at certain time intervals and thus accept higher costs if the service life of those cables is not exhausted.

i.Cee changes the game here. The module can automatically trigger an alarm or an emergency stop of the system if defined limit values are exceeded. This can prevent immense consequential damage and even total failures, which can cause several tens of thousands of pounds in damage and lost time, for example in automotive production or in crane applications like ports. In addition, the i.Cee module automatically calculates the most economical time for maintenance operations and cable changes.

“It is therefore designed to reduce both maintenance costs and very costly downtime,” Leonard says. “We calculate that investing in a CF.D/i.Cee system pays back in a few months and an ROI of over 500% per year.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>