Posted to News on 9th Jul 2021, 08:58

Developing linear bearings for six generations

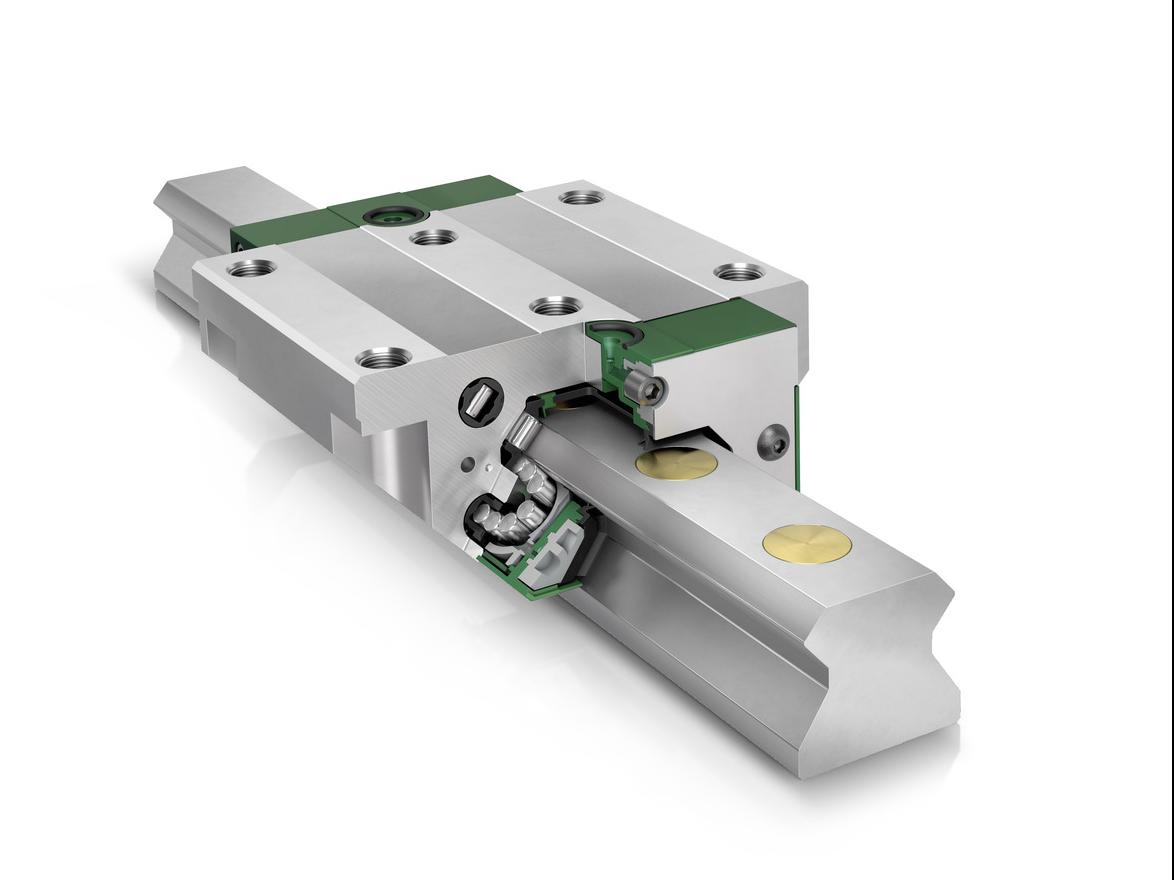

New era of recirculating roller guidance systems dawns for machine builders

Are shorter assembly times, lower operating costs and a longer operating life decisive arguments for you? There is no need to look any further than Schaeffler's new development, states the company.

“Since the 1980s, Schaeffler has been setting the benchmark in terms of the highest rigidity, load carrying capacity, precision and reliability with its RUE linear recirculating roller bearing and guideway assemblies,” it says. And it points to its 6th generation of recirculating roller guidance systems, the RUE..F, for demonstrating just how far this technology has come.

“Having outstanding expertise in the field of rolling bearing solutions for production machinery and automation technology, which is hardly matched by any other company, the RUE..F has a completely new design of rolling element recirculation. This results in smooth-running characteristics, with significantly reduced displacement forces,” Schaeffler adds.

Key benefit

With a focus on operating costs and environmental protection, one of the key benefits is that lubricant consumption has been reduced by up to 50%. This has been achieved by optimising lubrication channels, enhancing flow and efficiently transferring lubricant toward the critical point.

A new standard of accessories has also been adapted, including a mounting rail and closing plug. Assembly is now faster and more convenient. The RUE..F is available with a newly developed covering strip (ADE), which simplifies installation to within one tenth of the installation time previously required.

Upgrade pay-off

“The upgrade to the new RUE-F..pays off, whether you're as part of original equipment or as a retrofit, this design is for machine manufacturers and machine operators in equal measure.”