Posted to News on 15th Feb 2021, 10:20

Drive controllers boost productivity of winding machines

STOBER drives are helping Leicht Stanzautomation to compete in the Champions League' of machine building

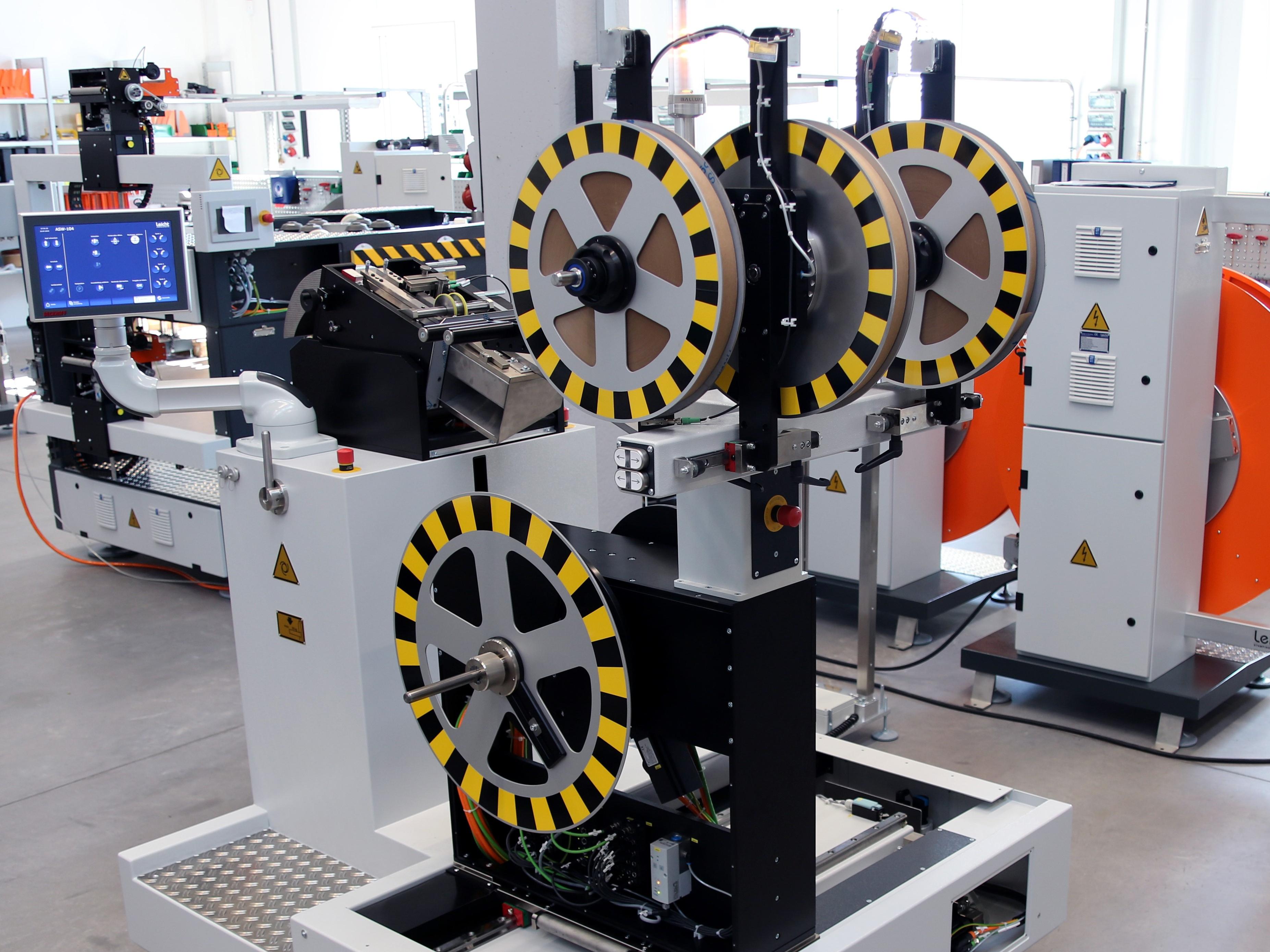

Leicht Stanzautomation, designer and manufacturer of systems for winding and unwinding strips and wires, has specified STOBER’s SI6 series drive controllers for its latest generation automated multiple winders.

Thanks to its economical space-saving design, the STOBER SI6 multi-axis drive concept is said to give the new Leicht system "dramatically increased performance over previous generation systems and is the key to the cost-effective productivity of the system".

What makes this generation of winding machines different is that the system changes the reels automatically. This means that production at the upstream punching machine does not have to stop, as the reel is simply changed for the next available reel as soon as the preselected quantity has been reached.

‘Reel’ speed

After components are punched, the new machine automatically winds them in a few minutes. The reels are driven by coaxial synchronous servo geared motors and "it takes barely two seconds to change from reel to reel with a planetary gear unit".

The highly dynamic drive controllers operate reliably, functioning unobtrusively in the background, even during the most challenging operations.

Another space-saving right-angle gear unit handles the precise feeding of the strip. Consequently, STOBER’s SI6 compact drive controller has enabled Leicht to increase performance of their new machines substantially.

Jurgen Leicht, managing director of Leicht Stanzautomation, says: “Dynamics and speed are extremely important for the user to be able to operate cost effectively. The faster the processes are, the more productive the machine is, as the time factor is critical for customers if they are to be competitive. “We have a total of seven STOBER drives installed in the system," Leicht explains.

To ensure complete reliability, STOBER’s STO (Safe Torque Off) and SS1 (Safe Stop 1) functions are integrated within the Leicht systems. In the SI6 series, these are certified in accordance with EN 13849-1 and can be used without function tests that interrupt production.

Scaled without limit

"The drive controller has a width of only 45mm and is designed as a multi-axis drive controller," says STOBER representative Markus Stolowski, who has worked alongside Leicht Stanzautomation for many years. "A single SI6 drive controller can control up to two axes. Thanks to the multi-axis drive design, the number of axes to be controlled can be scaled without limit."

Installing individual STOBER components couldn’t be easier. The patented Quick DC-Link modules were simply clicked into the standard copper rails for power distribution, which enables the simple installation and connection of the drive controllers. "The electronic geared motor nameplate is available with the HEIDENHAIN EnDat 2.2 encoder system and easily and reliably handles parameterisation of the motor and gear unit data, the STOBER expert explains. "Previously, only motor parameters could be transmitted, but now we also make it possible to transmit additional application-relevant gear unit data completely electronically."

The individual devices are connected to the central PS6 supply module. As a result, there is no need for decentralised supply modules or fuses and cabling for each axis, and Leicht saved a tremendous amount of space within the control cabinet. This means that Leicht’s new generation systems enable customers to have a considerable number of winding machines in a small installation area.

Additionally, the new ASW is easily accessible, and the user can conveniently operate the system using a ten-inch display.

Long-standing partnership yields benefits

Jurgen Leicht underlines this, saying: "The development of the new multiple winder system is based on our own experience and in collaboration with STOBER to integrate and design the drives. They have been with us from the beginning and have supported this new machine from conception, through the design phase, right up to commissioning."

One of the real strengths pointed out behind the Leicht-STOBER relationship is the technical consulting and support provided by STOBER that goes back almost 25 years. This not only makes it possible for the two companies to interact positively with each other, but to benefit from shared knowledge in the development of market-leading products, like the new automated multiple winder.

Using a football analogy, Jurgen Leicht comments: "STOBER's support helps us continue to qualify for the Champions League of machine building."

STOBER SI6 drive controllers

STOBER’s latest SI6 drive controller is a modular and scalable rack system for machine builders. It has multiple axes that save end-user costs in hardware, energy use and installation. The double axis module, which provides 2 x 5 amps, is just 45mm wide yet delivers a position, speed and current cycle time of only 62,5 µs.

It is available with integrated EtherCAT and PROFINET communication, as well various safety options, including FSoE (Safety over EtherCAT). The SI6 can control rotary synchronous servo motors and asynchronous motors, as well as torque motors. It will also work with HIPERFACE DSL one cable encoder systems.

With five sizes and with two power options, the STOBER SI6 saves both space and energy, and is so compact that a 20 axis system occupies a space of just 495mm, it is stated.

Leicht has integrated STOBER’s patented Quick DC-Link system using one bus voltage, which means that energy generated from one drive can be harnessed by the other modules, resulting in more power for less investment.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Centrix House

Upper Keys Business Village, Keys Park Road

Hednesford

WS12 2HA

UNITED KINGDOM

+44 (0)1543 458 858