Posted to News on 11th Mar 2021, 09:05

Driving forward HMI design in automotive

COPA-DATA provides HMI upgrade for tailored usability

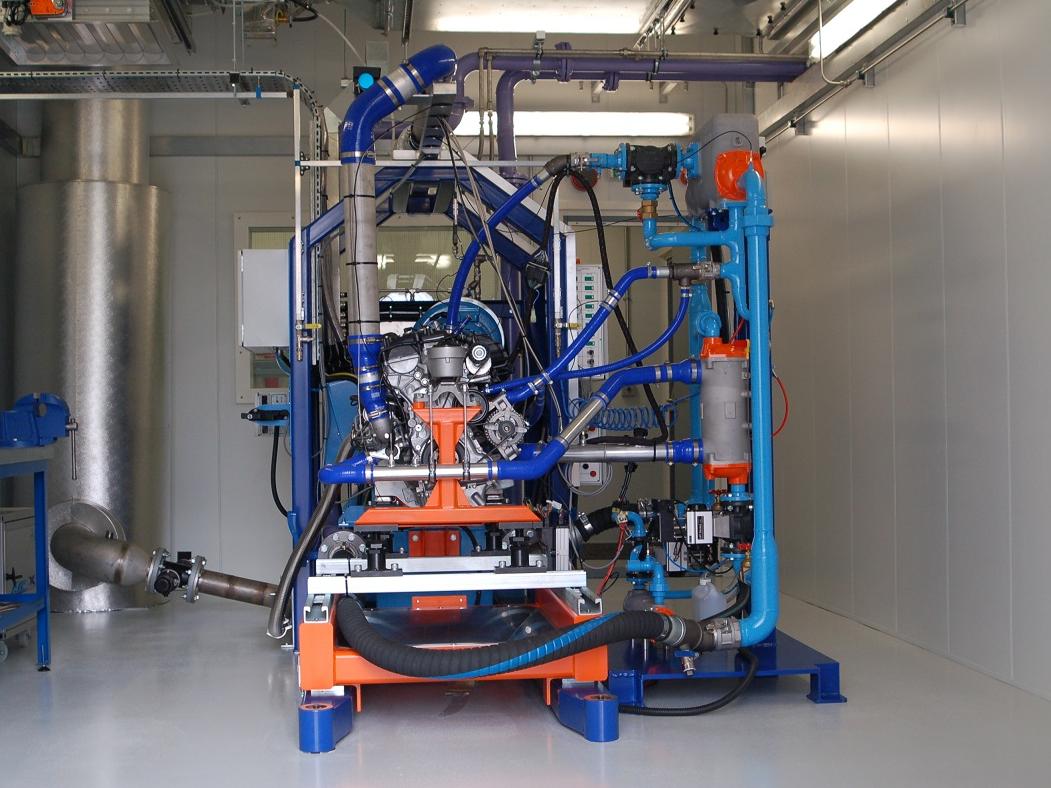

Based in Worcester, Dynamometer Services Group provides engine, transmission, component and vehicle testing. Specialising in new and remanufactured dynamometers, DSG delivers a modern service by incorporating advanced digital control and data acquisition systems through COPA-DATA’s zenon software platform.

The technology is used by the automotive sector to accurately measure the torque and rotational speed of an engine, therefore calculating the engine’s power.

Project range

DSG provides dynamometers to users – from large-scale engine manufacturers, right through to small manufacturers and niche projects, such as engines for aerospace and classic formula race series. HMIDynamometers must be accurate. But, more importantly, they must accurately relay their measurements back to an end user in an understandable manner.

This is typically visualised through a human machine interface. HMI should seamlessly connect human and machine – in this case, the operator and the dynamometer. DSG sought an upgrade to its existing 28 HMI screens to improve user friendliness, usability and general aesthetics, and turned to zenon by COPA-DATA and its professional services offering for help.

COPA-DATA’s professional services provides customers with complete project management, from concept development through to coding support and workshops. For DSG, this offering was seen as an ideal opportunity to update its group of 28 HMI screens, while also tailoring zenon for the project’s unique requirements.

Complex visualisation

zenon is an open-design software platform that can be used for complex process visualisation. It can offer classic HMI tasks, like operating and observing processes, through to more complex actions typically associated with supervisory control and data acquisition (SCADA),such as archiving data and analysing trends.

As an HMI for DSG, zenon has been used to modernise the way the company communicates measurements of its dynamometers. Before the project, DSG used a variety of HMIs, some of which were outdated, compared to the company’s engineering expertise in the sector. Standardising the platform used across these HMIs provided a much-needed upgrade, both visually and ergonomically.

Simple improvements, such as aesthetic design, made a big difference. By using a standard application of colour pallets across the HMIs, zenon helped to keep projects look and feel consistent throughout the HMI. For the end user, this reaffirms trust in the dynamometer and therefore trust in DSG.

Colour customisation

The use of the colour pallet functionality also allows the customer to customise HMIs to specific colour specifications. Blue and white branding? Blue and white interface. This is particularly beneficial for DSG’s sales process.

zenon also ensures consistent styles. In the original version of the project, the HMIs used several styles in different parts of the projects. While this may sound minor, it is ultimately very distracting and confusing for the user. The new style consistency makes it easier for a user to perform tasks without confusion.

Overhauling a previously cluttered interface with zenon allowed DSG to reduce engineering time for operators by enabling much better usability. For instance, symbols were created for the significant components of the project, which could reduce the number of customer changes in the future. Symbols were also used to improve the otherwise cluttered navigation of the HMI, creating consistent navigation options across multiple screens.

Greater efficiency

Drop-down lists were also minimised. Removal of some of these outdated and difficult-to-use lists allowed DSG to replace them with more efficient buttons and pop-ups. Because users are more familiar with these visual displays, the user experience is improved.

The HMI overhaul has also allowed DSG to future-proof the technology for its end users. For instance, the application of layers in the zenon Editor can reduce the volume of engineering time with future project adaptions. Combined with better data display, the machines become much easier to read and therefore far more valuable.

Suite 42, Fourth Floor

Greyfriars House, Greyfriars Road

CF10 3AL

UNITED KINGDOM

+44 (0)1633 415338