Posted to News on 19th Oct 2020, 08:57

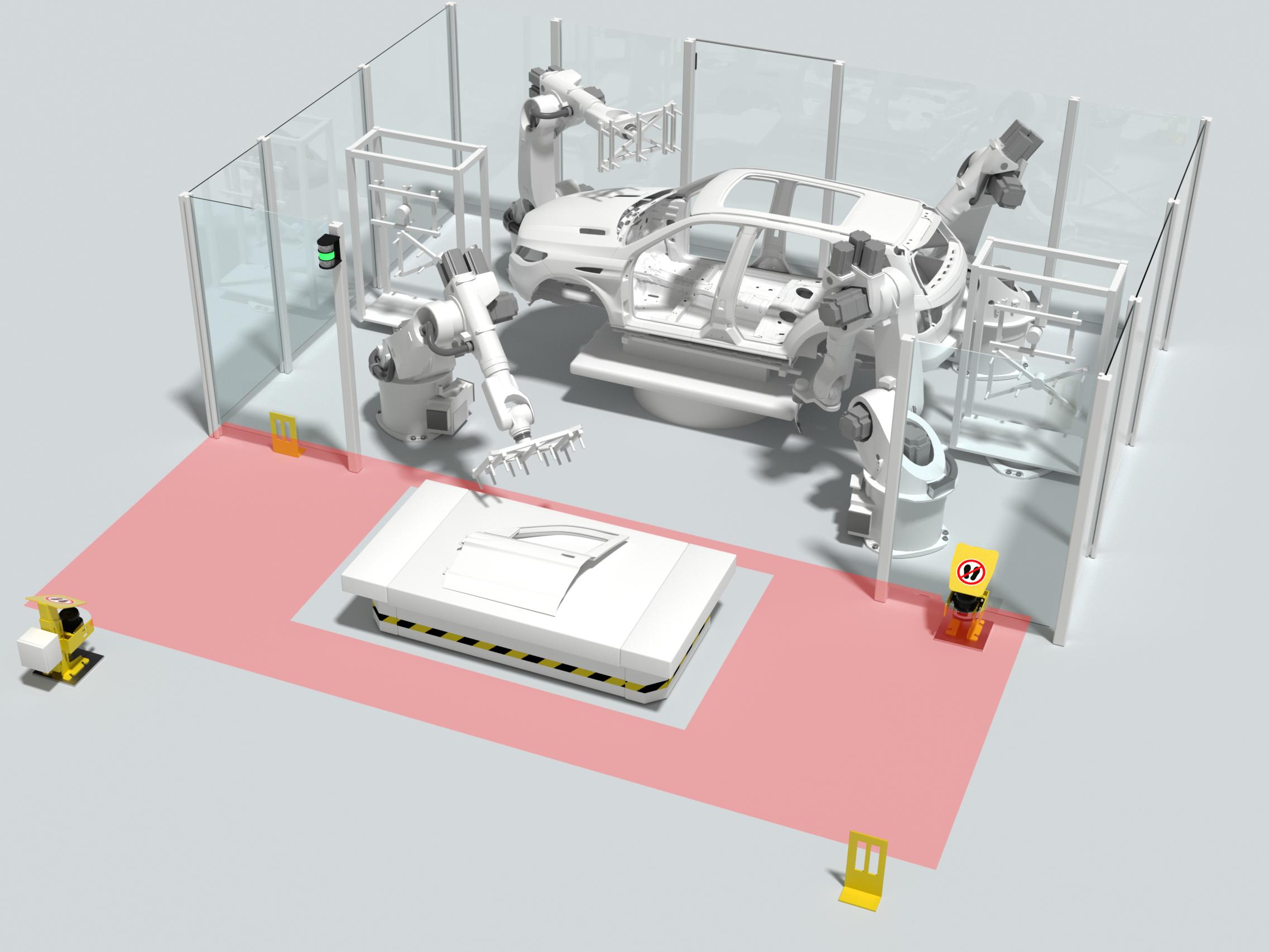

Dynamic safeguarding of AGV/robot transfer stations

Leuze is highlighting safety solutions around robot transfer stations and conveyors

In some production processes AGVs are loaded and unloaded by robots, meaning that the safety concepts for the localised transfer stations must be designed from the outset for automated movement. Leuze says that it offers a safety solution which dynamically safeguards the area of the transfer station, in which the area is monitored by two safety laser scanners. When the vehicle enters the monitored area, the monitoring dynamically adapts to the vehicle position and blanks out the AGV footprint from the monitored area.

The advantage of this approach, says Leuze, is that the presence of people (or their entry to the zone) is continuously monitored. So the vehicle can move through the monitored area during the loading cycle whilst its surroundings remain fully guarded, because the system can detect whether a person is walking next to the vehicle. The solution also allows for vehicle loads of varying widths, as well as and the transportation of parts that protrude at the front. The system works autonomously and Leuze says that it can be easily integrated into the safety circuit of the system via the 2-channel safety output.

Access guarding on multi-track transport systemsMulti-track transport systems often require a safety concept that caters for the combination of smooth processes and complete safety at the same time. In this case, Leuze states that it has a safety solution that also works well, citing the example of a pallet discharge via a gravity conveyor which is fed by a cross conveyor. Access guarding takes place via two vertically oriented safety laser scanners, and these monitor the entire transfer area of the cross conveyor. By switching the protective fields, the protective function is only released for the conveyor on which a pallet is discharged, with the system receiving information about which conveyor is used from system control.

Complete access guarding during pallet dischargeLeuze says that the advantage of this solution is that the entire access area is completely monitored at all times. It is also said to be easy to set up and install, as it needs just two safety laser scanners to safeguard the whole transfer area, with no additional trigger sensors required, despite the close proximity of the conveyors.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500