Posted to News on 16th Nov 2016, 21:25

Easier, faster robot programming for assembly operations

RARUK Automation, which supplies the Universal Robots series of collaborative robots (cobots) in the UK, together with complementary products including Robotiq grippers and force/torque sensors, is partnering with ArtiMinds Robotics. ArtiMinds has integrated the latest technologies in machine learning, motion planning and motion control for robotic manipulation into a robust, easy-to-use software package that is fully compatible with Universal Robots and Robotiq force/torque sensors. The software greatly simplifies the teaching of assembly and similar operations and, therefore, creates new application opportunities for collaborative robots.

The ArtiMinds RPS (Robot Programming Suite) is an offline programming package that works with popular CAD packages. It offers fast and easy set-up of Universal Robots without the requirement for any expert knowledge. In an independent external benchmark test, a typical force-controlled robot task was set up in five minutes instead of days using conventional programming.

The software is designed to work directly with CAD systems, so users can import their applications as a solid model and program the robot offline. The Universal Robot and Robotiq gripper are already drawn in the package. As a result, ArtiMinds makes it possible to have a 3D representation of the full application, complete with robot and gripper. The principal benefit is the visualisation of programming tasks and process simulation for motion optimisation and collision avoidance.

A further major advantage of RPS is rapid ROI, which can typically be achieved within the first project. This is because maintenance, adaption to process variances and transferability to other tasks become easier. Furthermore, the software helps to make processes more robust, so system failures can be avoided.

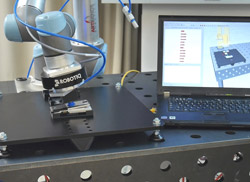

Example assembly application

The case for fast payback is illustrated by an automotive customer case study involving the automated insertion of plastic safety rivets. Due to part variances and displacements, an adaptive solution was required. By using ArtiMinds RPS, the application could be easily programmed in just two hours by an experienced user. Compare this to approximately 200 hours that would be required by a senior expert using conventional robot programming and the advantage is clear to see. The programming costs using ArtiMinds were estimated at less than EUR500, as opposed to the EUR20,000 it would have cost otherwise. In addition, the ArtiMinds set-up offered the customer ease of modification, cycle time optimisation and online quality control.

ArtiMinds enables programming to be completed in three simple steps. The first permits users to compose task sequences simply by using drag-and-drop building blocks such as 'force-controlled insertion' and 'move without collision' provided by the extensive software library.

Next, the building blocks are parameterised for the specific application. Here, the user is guided through the process by an interactive wizard. This can be performed online either by using the teach pendant or by guiding the robot. Alternatively, offline teach-in via 3D visualisation or numerical input is also possible.

The final step simply requires a single mouse-click on the simulation or execution button. This triggers fully automated motion computation, robot program code generation and robot motion simulation, followed by program transfer to the robot controller. The robot then performs the programmed tasks.

ArtiMinds RPS automatically outputs a comprehensive program in the native robot programming language. The program can therefore simply be transferred across to the robot (USB stick is the easy option), and operations can commence.

To modify the robot program at a later date, a PC with ArtiMinds RPS can be connected and the project file loaded. Now, the program can be modified or building blocks re-parameterised directly at the robot. As a result, modifications can be performed very quickly, concentrating solely on aspects to be changed. Alternatively, direct editing in the robot programming language is also possible.

Among the numerous available options is the force module, which is designed primarily for insertion tasks whereby using a force/torque sensor the robot can find an object or a feature's position. For example, inserting a bolt into a hole that is not always in the exact same location.

ArtiMinds software can be used to program robots for assembly (mechanical and electrical), handling, packaging, QC and laboratory operations. It supports CB2 or CB3 controllers used on UR3, UR5 and UR10 Universal Robots.

Follow the link for more information about ArtiMinds RPS from RARUK Automation, a dedicated automation company from RA Rodriguez (UK) Ltd.