Posted to News on 9th Mar 2022, 08:54

Elesa has a firm handle on high temperatures

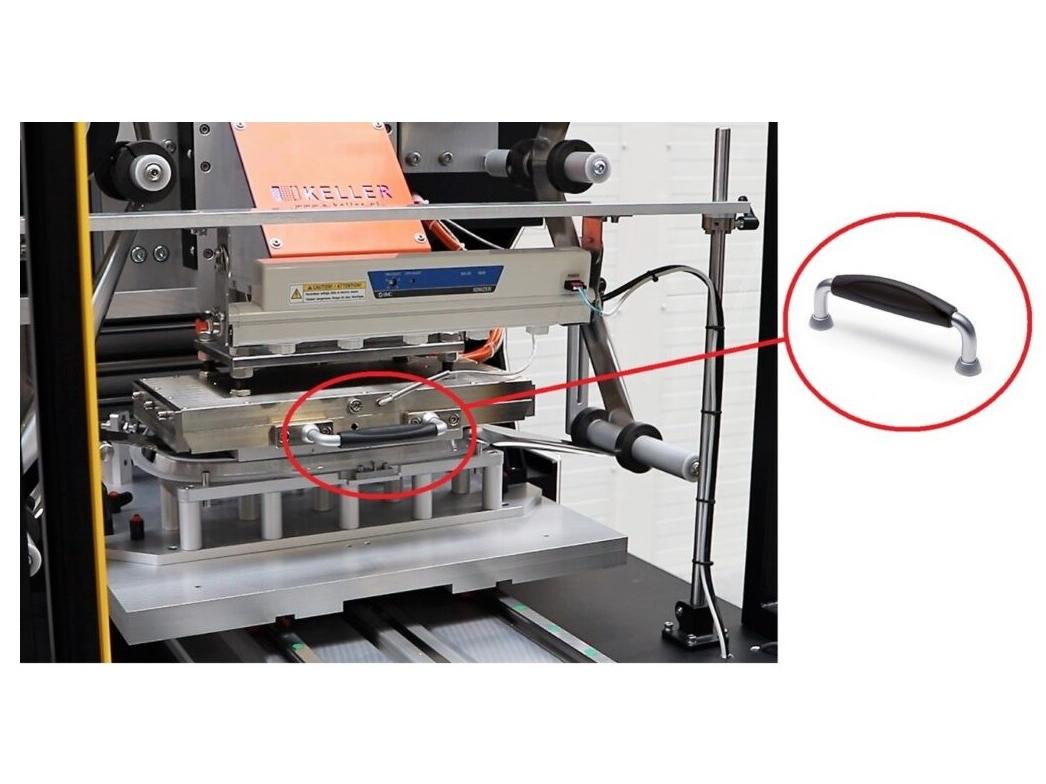

Machine and equipment builder Keller opts for heat insulation solution

Keller specialises in the production of machines for industrial printing across a variety of sectors. An engineering solution was required for a new project that needed a handle that compliments a machine operating up to a temperature of 250°C. This machine heats moulds and maintains low cooldowns, with changeover times being a crucial factor for optimal operations.

Elesa proposed the MMT. handle for heat insulation, “which has been adopted by Keller to serve as its ideal solution”, it reports.

The handle is composed of a round steel cross-section bar, with fine ground matte chrome-plated surface and a heat insulation element in glass-fibre reinforced polyamide-based technopolymer. The handle is available in black colour, with matte finish.

Heat transfer minimised

“A series of internal aeration canals of the technopolymer heat insulation element allows excellent heat insulation, which minimises the heat transfer to the operator’s hands, ensuring a firm and safe grip,” states Elesa. “The ergonomic design helps to facilitate the grip, keeping the operator’s fingers away from the heat source. Heat insulation is the fundamental feature of the MMT handle, which also makes it ideal for use on opening doors of stoves and fireplaces.

Testing was carried out internally via Elesa laboratories, with continuous working temperatures up to 200°C. The results showed that the MMT. handle transmitted a temperature between 65°C and 90°C on the element in technopolymer.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>