Posted to News on 21st Sep 2021, 08:58

Enclosures specified to protect the UK’s machines

Chris Lloyd, managing director of Spelsberg UK, offers his take on the key requirements OEMs need to consider when choosing their enclosure manufacturer

Enclosures provide a safe and secure location for electrical power and control components, as well as protecting against environmental conditions. As such, the choices made in selecting enclosures for industrial applications can have a significant effect on the performance and reliability of equipment.

For industrial electrical equipment to function, as well as protect machine operators, circuitry must be safely enclosed. As a result, it’s fundamental for original equipment manufacturers (OEMs) to carefully consider requirements before specifying an enclosure. Whatever the application, from a production machine through to a passenger lift, its performance and safety is only as good as the enclosure that protects it and this means achieving the right enclosure design for each situation and the associated conditions.

Getting the enclosure specification right

More often than not, OEM requirements are specific to purpose. Engineers can provide a set of needs that the enclosure has to fulfil, but often, wider considerations need to be taken into account, requiring the application experience of a capable enclosure manufacturer.

The application’s environmental setting is among the first considerations and protection against the elements can be crucial in an outdoor location, whether that’s on a ship at sea or enclosing switchgear at a solar panel farm. The ingress protection (IP) may need to reach the highest IP69 level even for indoor applications, such as the electrical distribution on milking parlour machinery, which must withstand high pressure water jets as part of a washdown.

Environmental conditions also take into account the internal area of the enclosure where high humidity and the potential for damaging condensation may require a counteractive specification. In addition to protection against liquid and physical particulates, fire resistance may be a requirement, most typically when used as part of fire detection and sprinkler systems. Resistance to impact, measured with the IK rating, is also a factor that determines not only the form and construction material of the enclosure, but also where it’s located on the machine.

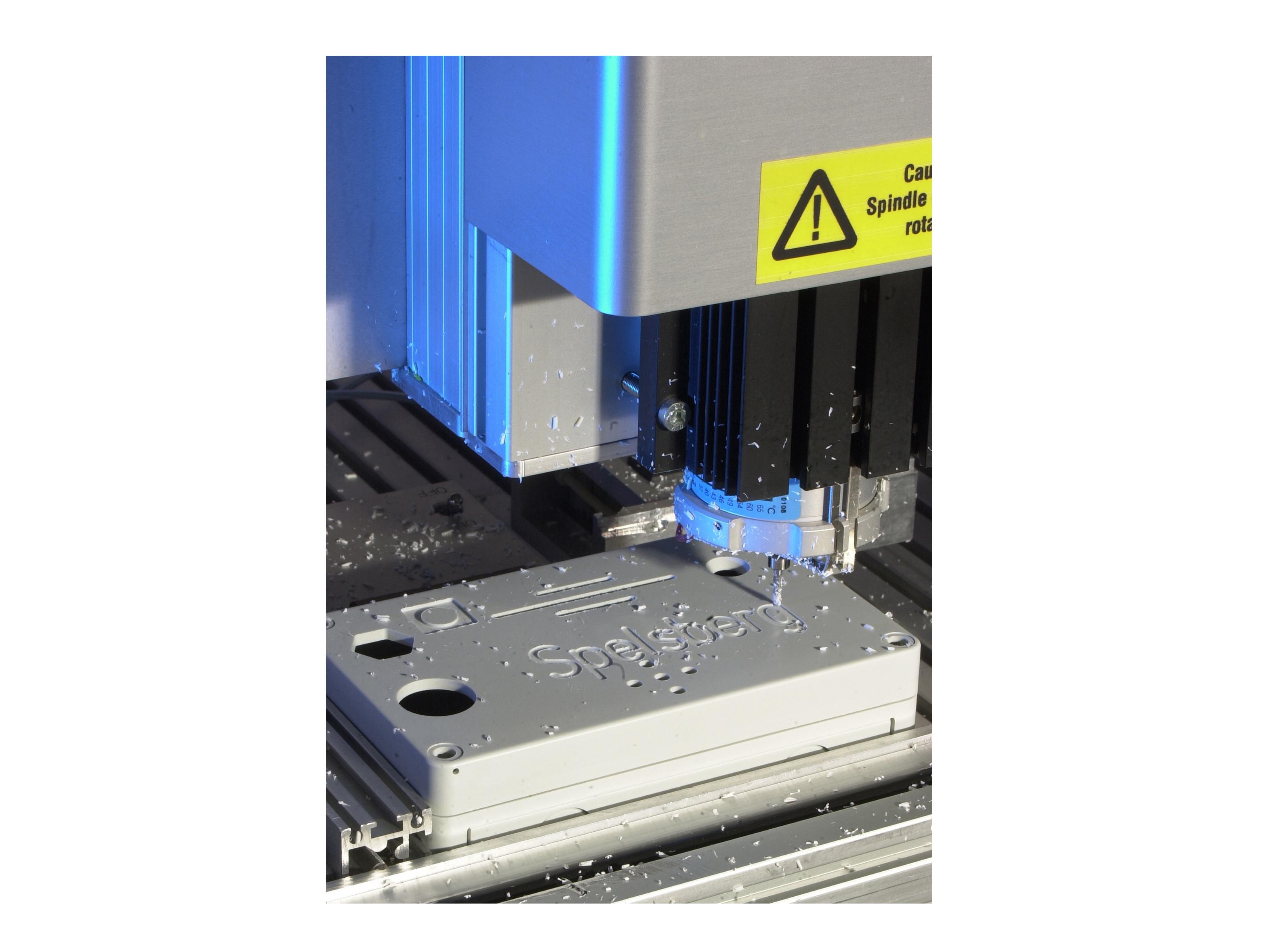

Position of the enclosure onboard a machine is nearly always predetermined and with the trend for reduced machinery footprints, it’s imperative that the enclosure is compact. At the same time, the enclosure has to be sufficiently spacious to accommodate the circuitry and its components with clearance to enable thermal cooling. Cabling, both inside the enclosure as well as its entry and exit points, must be well planned to allow for fast and easy installation, as well as simple future maintenance – especially if the enclosure is located in a cramped position. This can require enclosure walls with knock-outs to allow choice over entry and exit points or it can involve custom CNC machining to achieve the most effective cable routing.

In-house enclosure customisation is key for OEMs

Customisation of the enclosure may also be required should the OEM’s design incorporate functionality such as displays, touchpads or emergency stop buttons. It’s not just the physical form of the enclosure that requires attention but also labelling and referencing, so a printing service provided by the enclosure manufacturer can be of importance. In addition to printing, enclosures may need to be signified by various colour codes, or they may even demand their own coating for specific purposes.

An interesting example for Spelsberg UK included providing a military naval service with a ‘stealth’-coated enclosure for anti-radar purposes. This polymer coating is non-reflective of radar signals and is also self-extinguishing in the event of fire.

The crucial advantages of an enclosure manufacturer that can provide customisation services in-house include ensuring design integration, time saving and a single point of accountability. Working with a dedicated enclosure manufacturer that has a comprehensive range of products and services, rather than managing multiple outsourced service providers, the OEM has the confidence that the finished production integrates perfectly.

For most projects, speed is of the essence and a single manufacturer can manage customisation at a far faster rate than multiple parties. Finally, an enclosure specialist like Spelsberg that can manage the entire project, from creating samples to full production runs, ensures a high-quality product and that all of the OEM’s requirements are achieved.

Testing is a crucial stage for an OEM and it’s important that the enclosure vendor can provide a sample at the earliest available opportunity in order to maintain project pace. It’s crucial that the prototype is a close design to the production enclosures that will follow, and this means that getting it right first time is key. For the speed factor, it also makes sense if your sample is developed locally; a 3D printing service that creates close to production samples can be a preferable option for faster testing and approval of the most complex enclosure designs, which can be achieved within 24 hours.

Durable, easy to integrate enclosures for OEMs

The enclosures most typically specified for use by OEMs, or as a platform for customisation, include the TK, TG and GEOS ranges from Spelsberg. The TK range of industrial housings can feature knock-outs with pre-stamped membranes for swift onsite installation of cables while maintaining specified IP ratings. Constructed from glass-fibre reinforced polycarbonate, they achieve IK08 impact resistance and IP66 ingress protection.

They’re also available with a wide variety of options to provide a highly flexible mounting and installation. The similar TG range features a high gloss finish and smooth sidewalls for flexibility over customisation, as well as recesses in the cover for optional bore hole drilling.

The GEOS range, meanwhile, is ideally suited to outdoor environments, or indoor areas with harsh conditions. UV and weather-proof, GEOS features a ‘Drain Protect’ sealing system that channels liquids away from potential entry points. The enclosure also provides protection in aggressive atmospheres or against oils, greases and mechanical stresses.

Spelsberg also provides an assembly service, which can include pre-fitting of terminals through to installation of keypads and cable glands. This saves resources and time for the OEM, ultimately reducing time to market. The speed of service combined with the quality of the end product are the primary reasons why the UK’s major machine builders select Spelsberg as their enclosure partner.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1B Queensway Business Park

Hadley Park West

TF1 6AL

UNITED KINGDOM

+44 (0)1952 605849