Posted to News on 10th Aug 2021, 09:07

Environmental goals all set out

Parker Hannifin's new commitment: carbon neutral operations by 2040

In its 2020 Sustainability Report, Parker Hannifin has given a firm commitment to achieve carbon neutral operations by 2040. It has also established a series of emissions targets to ensure continued progress.

Scope I, II and III Emissions Targets

- Reduce absolute emissions directly from the company’s operations and indirect emissions from purchased energy (scopes I and II) by 50% by 2030

- Reduce other indirect absolute emissions related to materials sourcing, logistics and services (scope III) by 15% by 2030, and 25% by 2040

- Achieve carbon neutral operations (scopes I and II) by 2040.

“Parker has made great progress on our sustainability journey and we recognise the need to do even more,” said Tom Williams, chairman and chief executive officer of Parker. “Our technologies enable customers around the world to be cleaner and more efficient, and this commitment to reducing our own carbon emissions is another important step we are taking to create a more sustainable future for generations to come.”

The targets, featured in this year’s report, will be submitted for approval by the Science Based Targets initiative, which defines and promotes best practices in emissions reductions and carbon neutral targets in line with climate science. Parker’s long-term strategy includes actions to reduce its energy consumption, investments in renewable energy, and working closely with suppliers to further reduce energy use and emissions.

Enabling a sustainable future

The 2020 Sustainability Report also highlights Parker’s interconnected portfolio of motion and control technologies, which features a broad range of highly efficient products and systems engineered to help customers reduce resource consumption and greenhouse gas emissions.

“Parker delivers technology solutions that enable the adoption of cleaner and more efficient energy, electrification, light-weighting and other innovations with a positive, global environmental impact to hundreds of thousands of companies across the industrial, mobile and aerospace markets,” states the company.

These include the following, says Parker Hannifin:

- A comprehensive suite of engineered materials, such as thermal management, coatings, adhesives, and vibration control, that enable more electric applications

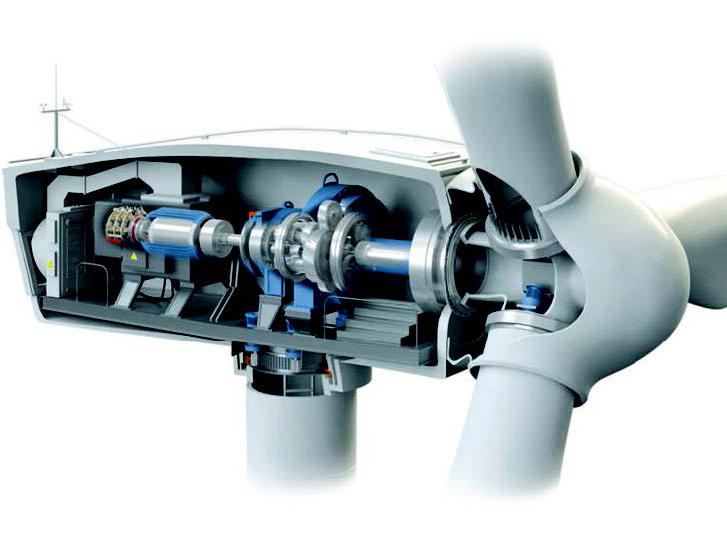

- A broad range of motion and control technologies to support the use of various clean energy sources, such as batteries, fuel cells, hydrogen, sustainable fuels and renewable energy

- Strongest motion technology offering, with electro-hydraulic, electro-mechanical, and pneumatic actuators, valves, pumps, motors, controllers, software and conveyance for more electric aerospace, mobile and industrial applications

- Exciting bill-of-material expansion opportunities both for onboard OEM equipment, as well as significant new infrastructure investment to support a cleaner technology world.

“With more than a century of experience, we are often called to the table for the collaborations that help to solve the most complex engineering challenges,” Williams adds. “Breakthroughs that make the world cleaner, smarter and safer would not be possible without Parker technologies.”

Sustainability Report key achievements

Other key achievements related to Parker’s sustainability initiatives detailed in the report include:

Safety is a core value that all Parker team members share and the company has reduced its Recordable Incident Rate by 72% from 2015 through 2020. In 2020, the recordable incidents per 100 team members was 0.40, a reduction of 35% from 2019

Since 2010, Parker has reduced energy intensity (MWh/USD) by 42% and greenhouse gas intensity (MT/USD) by 50%. In 2020, Parker’s climate disclosure score was ranked in the top quartile among diversified industrial peer companies

Today, Parker recycles more than 85% of waste generated by manufacturing operations and continues to reduce the volume of waste sent to landfills. The Parker-Hannifin Foundation has donated $64 million since 2010, including $6 million in 2020.