Posted to News on 4th Jun 2021, 11:55

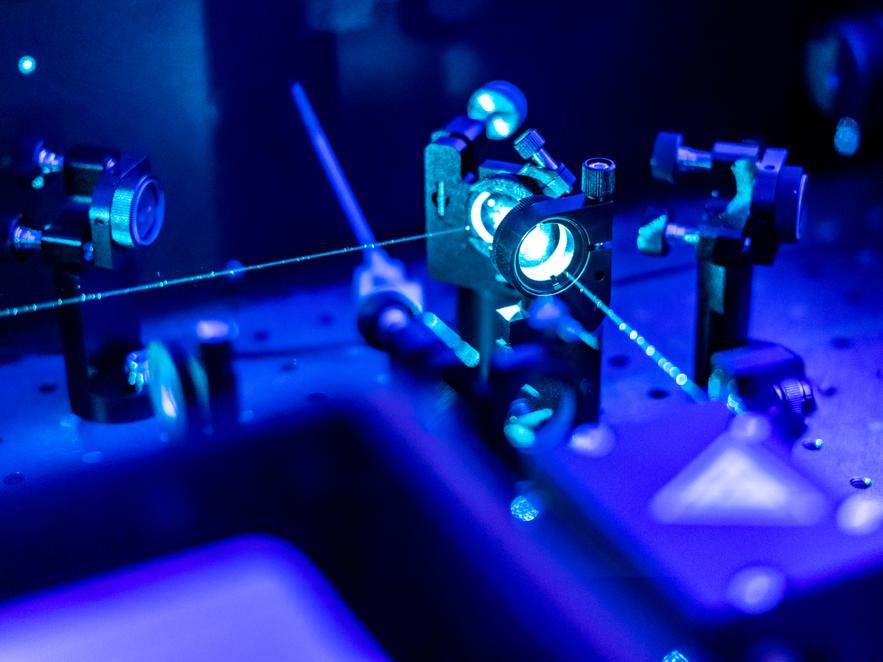

Essential measures on laser safety

Four-step approach to ensuring right levels of protection

With laser technology becoming more available to organisations and people at the individual level, safety concerns have arisen. “It is up to the organisations and the people to understand how lasers work, what can go wrong,” states EKSMA, “and how they can continuously improve their working environments to avoid harming themselves or the people around them.”

Everyone involved in the manufacture, sale, purchase, use and maintenance of lasers should ensure that the end user is safe. It’s not just an individual’s concern, but rather this responsibility falls on everyone’s shoulders, it continues.

How organisations and people protect themselves further is something that can be tackled in four steps, says EKSMA:

Understanding the international standards

As far as laser safety goes, manufacturers, professionals and laser use administrators adhere to global standards laid out by pioneers in the field. “An organisation can choose to work with a global perspective or lean on guidelines offered in its specific locality. Often, the two intertwine. While these standards are not mandatory per the law, they serve as guiding lights into how organisations should approach lasers and enable organisations to avoid common mistakes in the workplace.”

These guidelines often delve into permissible exposure and exposure limits, and these aspects are best assessed by a laser safety officer or an equivalent of this role. If nobody in the organisation understands lasers, there is a need to outsource professionals who can handle the equipment.

Identifying possible risks

The next crucial stage lies in understanding where possible risks are present, adds EKSMA, such as:

Untrained staff: take the example of a hospital where nurses work with lasers and have no understanding of how the equipment works. Not only can they harm themselves, but they can also harm the patients they handle.

Using a one-size-fits-all approach: lasers are different, and they all have differing dosimetry, spot size, application, wavelength and instrumentation properties. Approaching each laser using the same safety standards can pose a danger to the people in the organisation.

Exposure to laser energy: even with safety measures in place, it’s possible for people handling laser equipment to suffer accidental exposure to the lasers. It can cause eye damage, tissue damage or even gas explosions when the beams are direct. Or it can lead to indirect hazards, such as system failures and electrical damages. The laser safety officer or an equivalent must assess areas where such incidents can occur.

After identifying the possible risks, the laser safety officer or an equivalent must assess each risk's likelihood and effects.

Developing control measures

The organisation must have some measures to prevent the occurrence of the above risks as much as possible. “It’s only possible to do this after identifying possible loopholes in the safety system, enabling the organisation to draft some policies. The policies should indicate which employees have to follow them, why they are necessary, who needs to enforce them and how they will be monitored. As the organisation evolves and starts introducing more laser components, such as those from EKSMAoptics.com, the policies will also evolve. As such, everyone who handles the lasers should have access to the policies.”

The control measures should cover:

- Who can access the laser equipment?

- How should employees use protective devices?

- What coverings are needed to keep the laser energy within the room?

- Who should test laser systems before they are available to the employees?

- How should the laser systems be used? For example, when using components, how can employees ensure they do not pose harm to others?

- How can people remain safe when using the lasers?

A good example would be doors shall remain closed, but not locked, when employees are using lasers. This way, people on the outside shall not be in danger and those inside the room with the laser can get out, if an emergency arises.

Continuous auditing

Once all the control measures are in place, frequent audits will be necessary to ensure that employees have complied with the rules. “These will also cover the safety of the equipment used in the facility. The organisation should decide how many audits will be necessary based on their laser usage.

"For heavier uses, more audits will be necessary. Continuous education and training as laser system usage increases will also be essential to ensure that more people know how to handle lasers for the safety of all other users.”

At the end of the day, having a complacent attitude regarding laser safety can be dangerous to all involved, EKSMA concludes. “Organisations must put risk management plans in place and further ensure that their employees toe the line to avoid unnecessary hazards in the workplace. Individuals, too, must be aware of the necessary control measures and work to implement these whenever they use laser systems.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>