Posted to News on 15th Nov 2021, 08:57

Essentials of Budgetbeam flexible shaft coupling

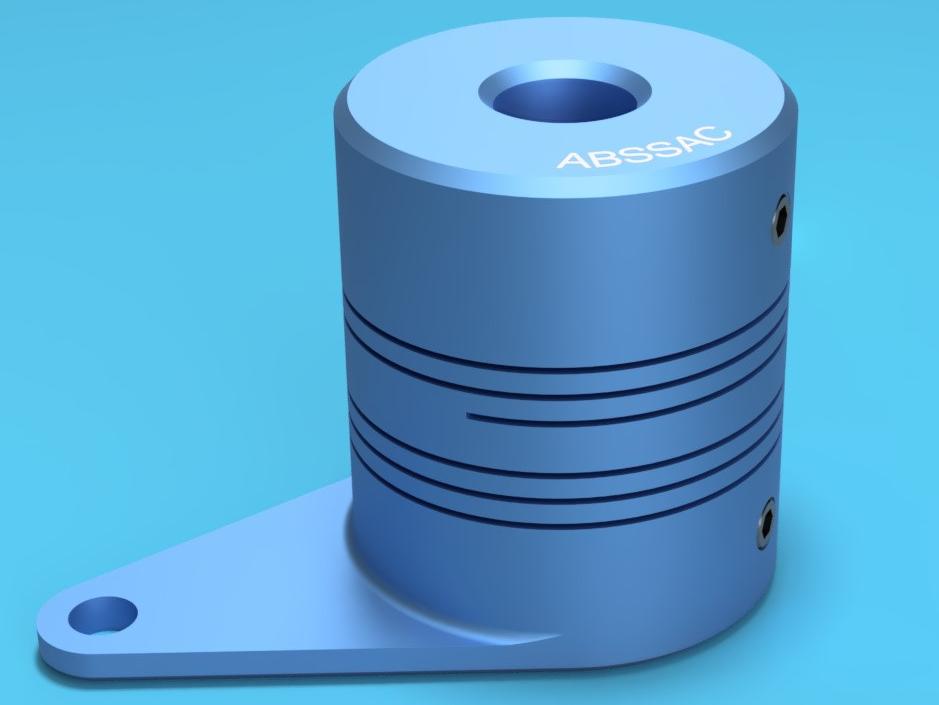

Manufacturing process translates into 'fit-and-forget' reliability

The Budgetbeam flexible shaft coupling has been continuously developed over 40 years of application experience, “where performance, reliability and low unit cost were the key objectives”, says ABSSAC. “Ideally suited to transmit torque values from 0.92Nm to 10.96Nm makes the single piece design ideal for use with encoders or small motors.”

There is no single shaft coupling design that is the solution to all applications; however, it is vital that the correct design type is chosen. The ideal shaft coupling has to reliably transmit torque, without backlash, but also absorb the shaft misalignments that can occur during operation. Correct specification is based on the key operating parameters, which can include the transmittable torque, operating environment, the direction of rotation and the angular or parallel offset of the shafts, to name a few.

“In short, a flexible shaft coupling isn’t just a simple physical connection, but a truly vital part of any machine’s functionality and, when chosen correctly, will deliver many years of reliable service.”

Dealing with shaft misalignments

Two examples are shown of a) the optimum shaft position, without any shaft misalignments; and b) angular shaft offset where shaft coupling operate with set parameters, which must be incorporated into the design capability.

The design of the Budgetbeam shaft coupling uses a proven helical beam geometry configuration in one, two or three beam starts, but maintaining a single-piece construction. “The unique design delivers high torsional stiffness and torque transmission capability, but also simultaneously absorbs shaft misalignments,” says ABSSAC. “A perfected manufacturing process ensures product quality, which ultimately translates into fit and forget reliability.”

Attaching the shaft coupling to the motor shaft and driven shaft couldn’t be easier, adds the company. Two designs are available. The set screw shaft attachment design uses two sets of grub screws at 120 degrees apart to affix directly on to the shaft at each hub end. Secondly, the integral clamp attachment design, which ensures shaft concentricity and total shaft clamping.

Special designs for individual applications

ABSSAC also offers the availability of special designs, which can suit individual applications on attachment, performance and budget.

Manufactured form high grade aluminium, the Budgetbeam shaft coupling can accept up to 5 degrees of angular and 0.1mm of parallel shaft misalignment. Stocked in metric bores from 3mm, 4mm, 5mm, 6mm, 8mm, 10mm to 12mm, the Budgetbeam shaft coupling is described as “a low-cost superior way of ensuring torsional wind up does not enter into your drive designs”.

Concludes ABSSAC: “The low-cost connection solution is ideal for closed loop encoder and servomotor applications, as well as lead screw to motor connection, both of which require high torsional stiffness to avoid loss of registration.”

The Budgetbeam shaft coupling is also available through on-line shopping